thanks for the compliments.

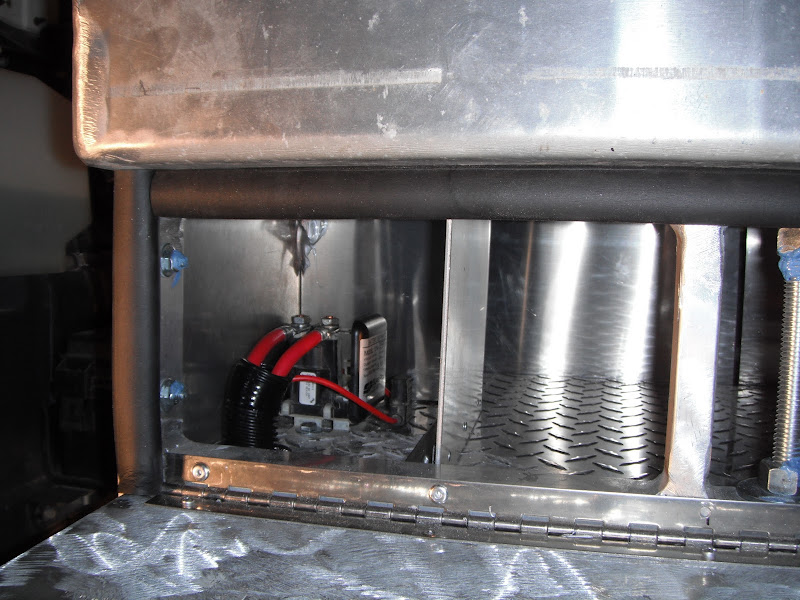

Here are some items to complete the battery box set up, a wrap around aluminum piece to protect the battery isolator from the storage area above the box, this area is a good size for some light items, it extends up into the deck frame area so is about 12' tall by the width and length of the box.

And to keep that stuff in there, I made up an aluminum door with a stainless steel hinge and lock with some door seal to keep it a bit dry.

With that out of the way, the next item on the agenda was to get the cassette toilet installed, these are designed for a wall thickness of no more than 2", and mine are 3" thick, so some creative work was in order, not hard just picky, I had to make up an extension on the water fill pipe( top door) which is a non standard size, I cut off a piece of the fill pipe, extended it with 2" ABS and siliconed it in place, used longer screws than supplied and was done.

The cassette door extended below the aluminum frame work and I had to trim a piece 3/8"th x 12" from the bottom so the door would sit flush, well here is a testament to the incredible strength of SIKA 251, that stuff will not let go, I cut between the fibre glass and aluminum with a box cutter (breaking two blades in the process) as much as I could, then started prying and hammering a chisel in there to separate it rendering the aluminum piece a useless chunk of bent metal. I officially recommend SIKA 251 as an adhesion product.

So the top door is the fresh water fill, and bottom is where the cassette stays(not there in this pic) and I noticed that I didnt get any pics of the actual toilet, so next time.

Unfortunately the build process will be slowed up from a planned trip, I was originally trying to make it to EXPO, but I couldnt get off work until the Friday when it starts, and since I live in British Columbia I wouldnt get there until it was over, so we opted to do a Death Valley trip instead, then spend a couple of days in Vegas for my B'day, so I will throw all the stuff back into the camper and start to get ready to go.

On another topic, some folk were asking about the weight of the Rhinocore, while the interior was empty, I had to get the truck weighed for re-registration (now officially an RV) and with the aluminum 1/4" corners all around, I estimate around 300-450 lb's of aluminum on there, and the actuators, it comes in at 1503 pounds. So probably a little over 1000 pounds of rhinocore product, camper size is approximately 13' x 6.5' x 3" thick at 5' tall, this includes 2" thick floor and roof, with 1/8"th fiberglass inside and outside.