put me in for a fuel tank skid too, if your gonna do a production run.

No production run planned. I have designed and produced quite a few different items, it is a long process to verify fitments on the different models and years, not worth the time and effort unless I know I have a fairly large market. However, I will make short runs if you can find at least 5 pre-orders (with deposits), of identical trucks and product, and supply me a truck. Good luck with that!:sombrero:

Nice pics of Smiley Rock - fun trail! It's is sad (or good depending on which one we're driving) to say, but the 140" wheelbase Dodge will outmaneuver our '12 JKUR.

Great job on the sliders. If you want to make some more to cover the cost, post up the pics on the Power Wagon Registry. The guys are hungry for a good set, and these look beefy. If they can be adapted to the 4th Gen, there is a huge market for them too. I think you'd like the step - it serves 2 purposes, entry, and it keeps the sides of the truck off stuff.

Mark

Same goes for the sliders! It does seem like there might be a market for those...how many model variations are there on those trucks? Anything I build here I am happy to replicate on a custom basis, or produce, given the right circumstances.

What you could do is use the look and feel of the dimple died mounts on your steps. Just cut a rectangular piece of plate and lap weld it to the under side of the 2.5x.250, then weld some triangular pieces that would tie the top of the step\shelf to the outer side of the tube. You could even get stylish and set the triangle pieces at an obtuse angle to the top of the step instead of perpendicular.

Thanks for the ideas, but I fear the dimple died holes (even reversed) will not provide enough traction. I am going to bend a tube step out from the rockers, and looking at plating the steps in with grip strut

http://www.mcnichols.com/products/trade-name/grip-strut-2/?pageCode=contentproducts I think this stuff should provide the best possible grip when packed with snow and covered in ice. I prefer the look of the flared holes by far; however, I will occasionally sacrifice style for pure function....ocasionally

Ohhh, those rockers are sexy

Thanks!

That is a sweet Dodge Rob! The sliders and skid plates look bomb proof and as someone already mentioned, the Carli stuff is top notch. I just helped a buddy install a Carli Starter Kit on a 2005 Quadcab with a Cummins. I was extremely impressed with quality of the Carli pieces and the performance of the kit.

Again, great truck! Bummer on the mileage though. Heck, my 35 year old 8,000 lb truck with a big block gasoline engine gets 10-12 on-highway and off-road.

Me and my right foot may possibly be the problem. I'm pretty sure I wouldn't get 12 mpg in your truck either

As far as the Carli stuff goes, I was very happy with the entire kit. I few items I have tweaked, but overall they have maximized travel and everything works and fits correctly thru the range of travel....something I can't say about quite a few "suspension" manufacturers.

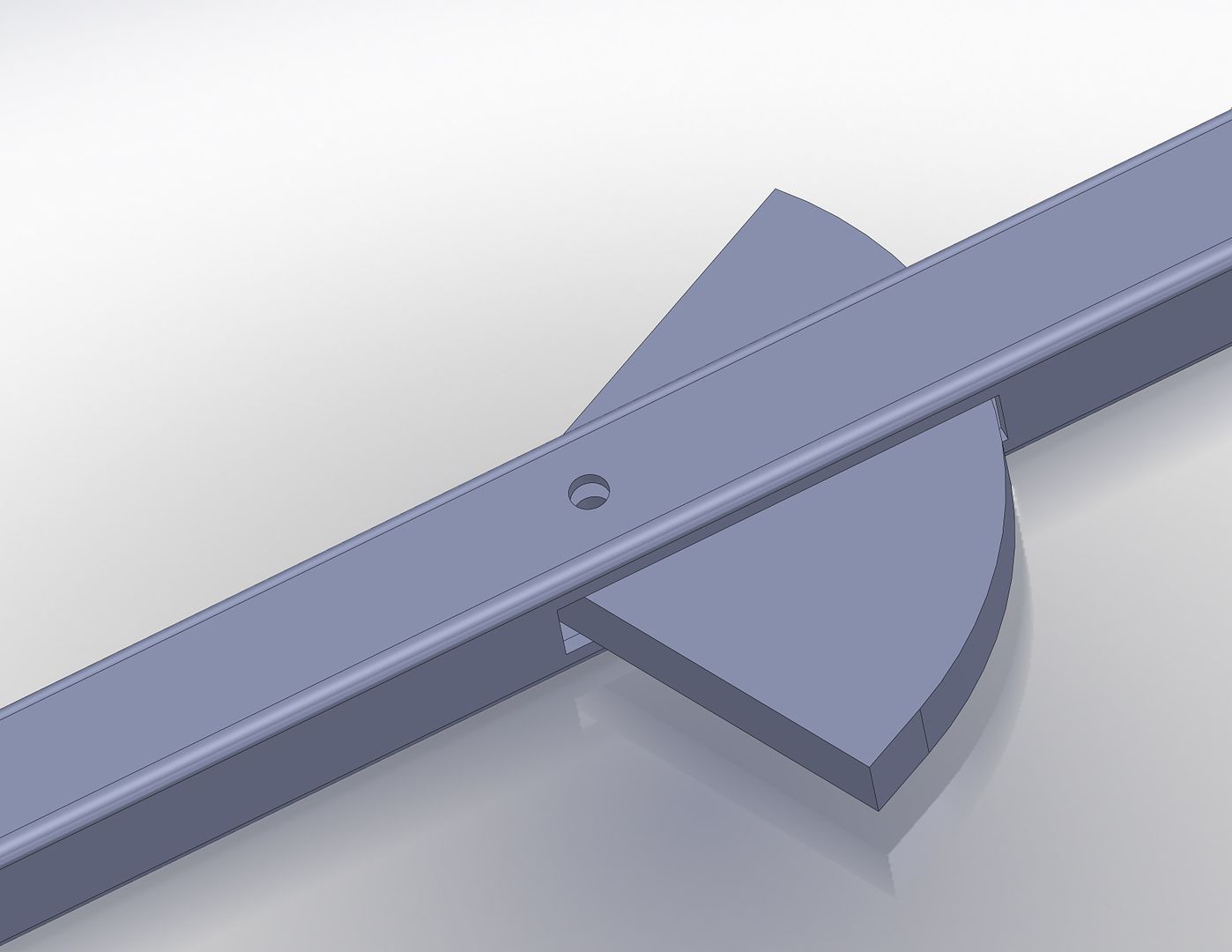

I know it would be a complicated PIA, but what if you have a little step that pivoted out from in the middle of the tubing? Need solidworks.....

Wala. Step idea.

If you did it right I think the tube could still be kept strong enough with some plating on the inside cuts. If you did it right I think it could be sprung open or closed with some kind of simple latch. If you wanted to get really fancy you could motorize it with an acuator an a door switch. With the cuts and step shape just right I bet you would hardly see it when it was closed.

Just an idea for ya.

I like that idea! It won't actually work here (the clearance behind the tube), but I will probably steal this idea in the future.:sombrero: The steps are planned to be full length to help access the inside of the camper thru the side window, roof rack and over cab basket as well as entry and egress.

.