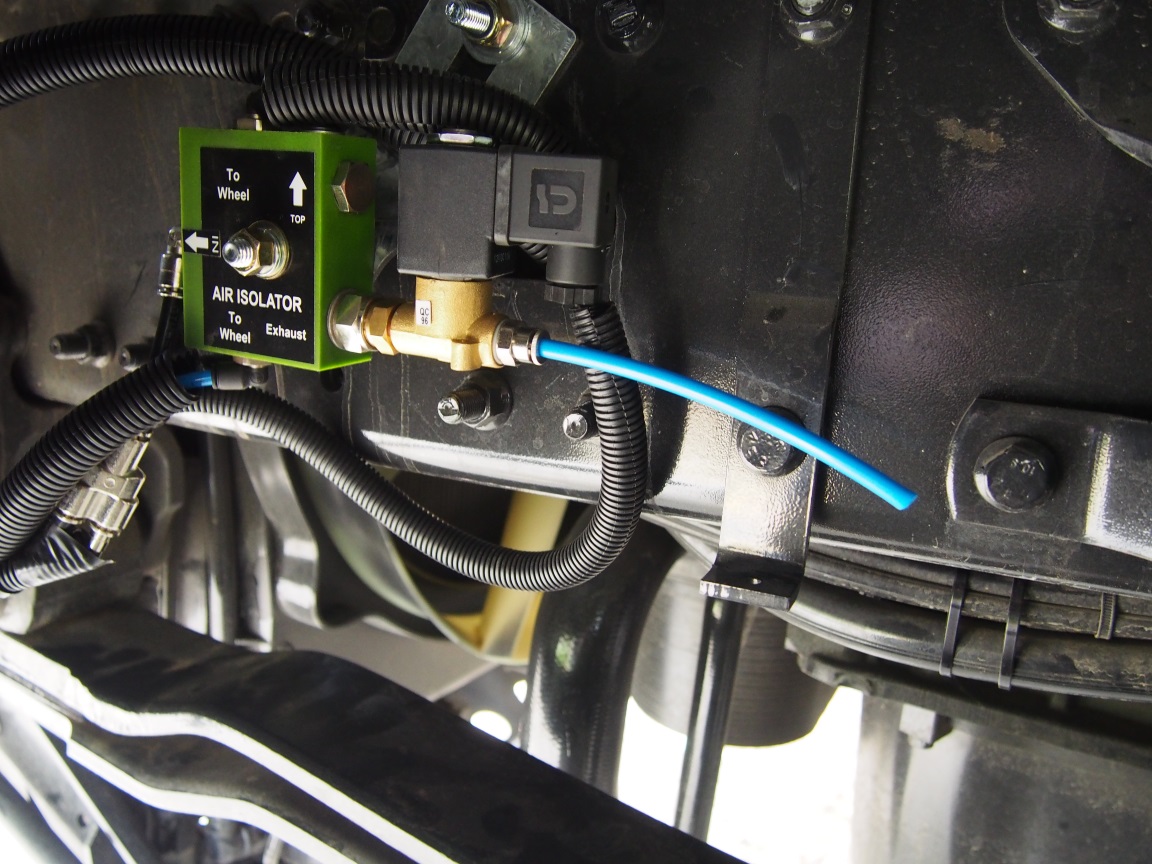

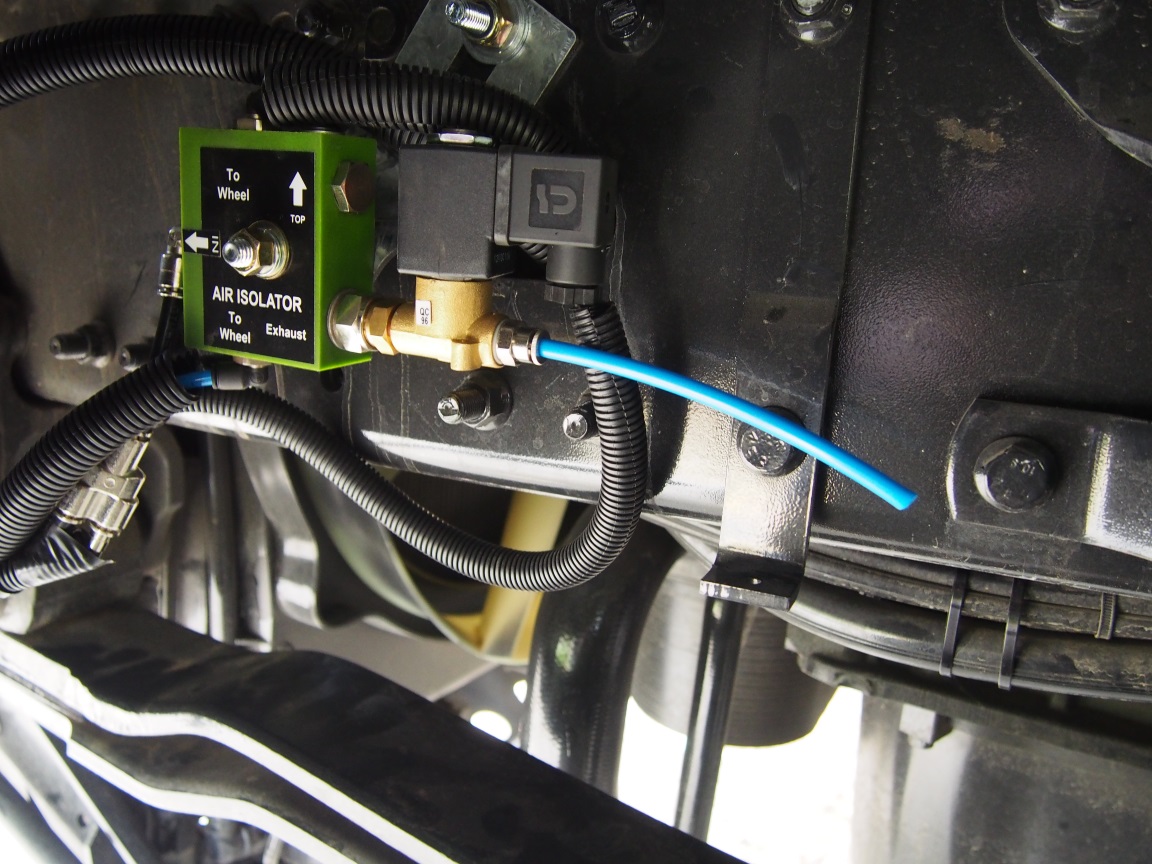

Central air tyre inflation system fitted

In the last 2 days I have gained an Air Central Tyre Inflation system (CTIS or Air CTI). So now I can change air pressures in the front and rear tyres whilst driving along

The system has external arms linked to a rotating hub. The arms stick out 50mm and I can see that there is the potential for an arm to be pulled off in the scrub. But the company assures me this is a very rare occurrence, and if it does occur the controller alerts you immediately. The drop arms have a sort of "fusible link" which detaches if it snags on something, and then you have to stop and re-connect it. We'll see how it goes...

Here are a few pictures:

It is controlled from the cabin by a series of solenoids. You can set different pressures front and rear. It takes a couple of minutes to go from (say) bitumen pressures to dirt road pressures.

Not as elegant as the UniMog solution (where the air is supplied through the centre axle hobs - so no drop arms required) but still a lot better than having to climb out and air up/down when you need to change pressures.

If you want more details, see this post on the blog: Air CTI installation

In the last 2 days I have gained an Air Central Tyre Inflation system (CTIS or Air CTI). So now I can change air pressures in the front and rear tyres whilst driving along

The system has external arms linked to a rotating hub. The arms stick out 50mm and I can see that there is the potential for an arm to be pulled off in the scrub. But the company assures me this is a very rare occurrence, and if it does occur the controller alerts you immediately. The drop arms have a sort of "fusible link" which detaches if it snags on something, and then you have to stop and re-connect it. We'll see how it goes...

Here are a few pictures:

It is controlled from the cabin by a series of solenoids. You can set different pressures front and rear. It takes a couple of minutes to go from (say) bitumen pressures to dirt road pressures.

Not as elegant as the UniMog solution (where the air is supplied through the centre axle hobs - so no drop arms required) but still a lot better than having to climb out and air up/down when you need to change pressures.

If you want more details, see this post on the blog: Air CTI installation