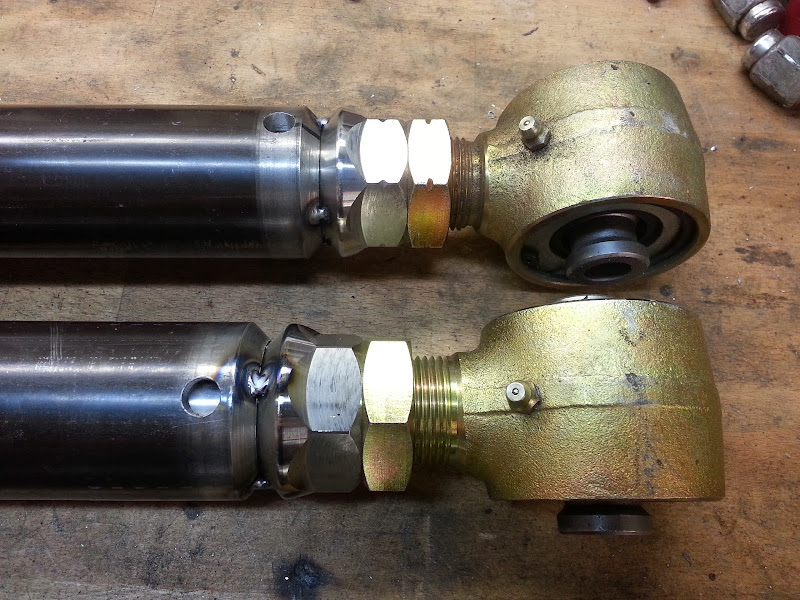

Received the drag link and tie rod from WFO Concepts, nice parts.

I'm using 7/8 thread Dodge/Chevy TRE's, also from WFO:

Drag Link: ES2027R and ES2027L

Tie Rod: ES2010R and ES2010L

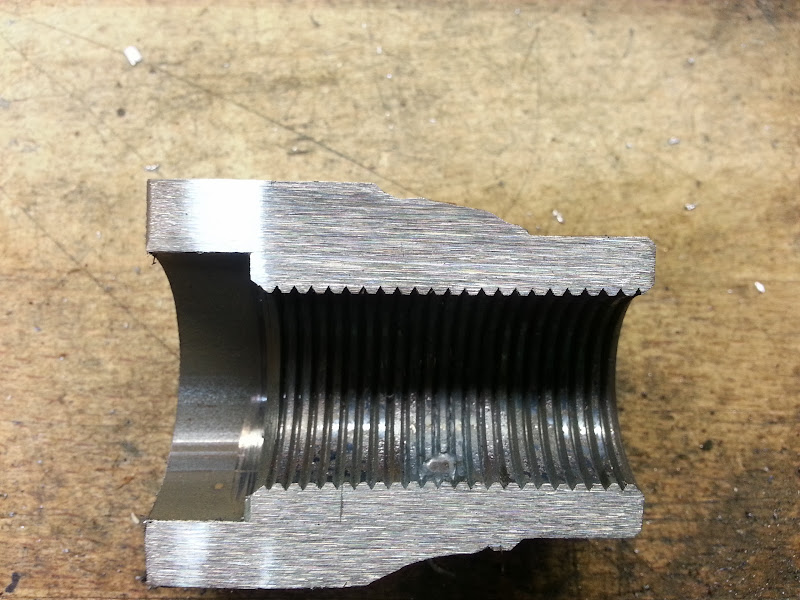

WJ pitman arm, reamed out for the larger TRE taper and filed the 'master' splines so that it'll key on my steering box whatever way I need it to

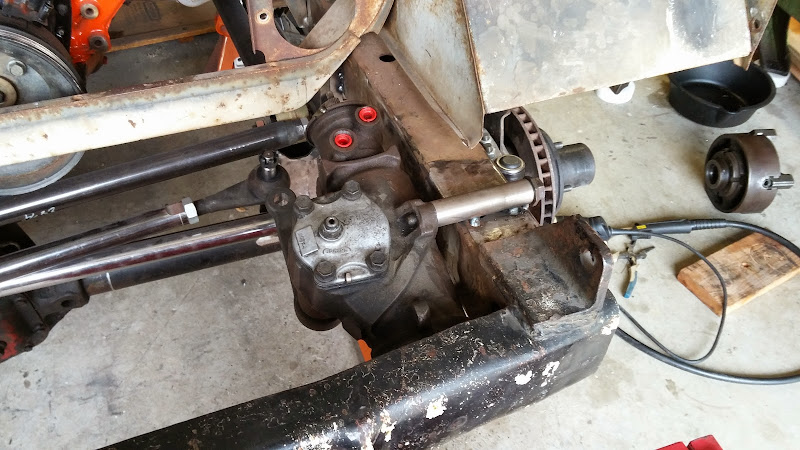

Suspension at ride height, Panhard bar not in place yet

Start to the steering box mounting

I'll sleeve the other 2 bolts through the frame, and tie this top sleeve in with some strap.

This weekend I was able to get the panhard bracket mocked up, and test out how it looks under articulation:

I wound up rotating the upper link mount backward an inch and the axle, to make room for the panhard bar mount. Using the ruffstuff panhard bracket in the highest hole, the panhard bar is almost exactly parallel to the drag link at ride height. Panhard and drag link lengths are identical. I want to try to measure how much bump steer this setup will give me, either by improving my CAD model to accurately include steering parts, or physically measuring it on the truck (or both). I may slot out the panhard bracket to lower the mounting hole (make a custom weld washer to locate the hole), or I may built my own panhard bracket, since this one takes up a lot of my very limited axle tube real estate.

Next steps, build a more permanent panhard bracket on the frame, figure out shock mounts, and try to get some idea of corner weights so that I can get springs to put on the coilovers. Cant wait to get it back to being a roller again soon.