Humvett;

Thanks, it is getting so close I can taste it!

Sooper camper;

I got tired of trying to drill it with my dull bits so I went to the cut off wheel for most of it. One of the rivets is impossible to reach with anything but a chisel. I also forgot that I turned the regulator on my compressor down to 40 psi for my plasma so the other air hammer was only getting half power! The better speedair from work was much more effective at any rate.

I spent a ton of time on making sure the track bar and drag link were the same length and exactly the same angle throughout the range of articulation and it paid off. At ride hight they are both sitting at 3* of inclination so pretty darn flat. I do have the f350 pitman arm on there. It came with the d60 and like you said it is a much stouter arm so I swapped out the f250 one for it.

I ordered my coilovers today. A huge thank you to sooper camper for helping me figure out what I needed. He is very knowledgable/helpful, and if it wasn't for your gentle nudging in the first place I would still be trying to figure out how to cram some some budget parts in there that would have ended up being a disappointment in the long run. With this much time and effort invested it is worth it to do it once and correctly. UPS tracking shows they will be here on Wednesday so I am super stoked to get the front end all wrapped up.

It feels like it is so close even though there are a lot of little things to take care of still. Most of it will have to wait until the coilovers show up. Tonight I trimmed the engine crossmember back enough to clear the track bar at full compression and removed the drivers side rear spring mount. That thing was a beast, but it's gone now!

Bye bye spring mount!

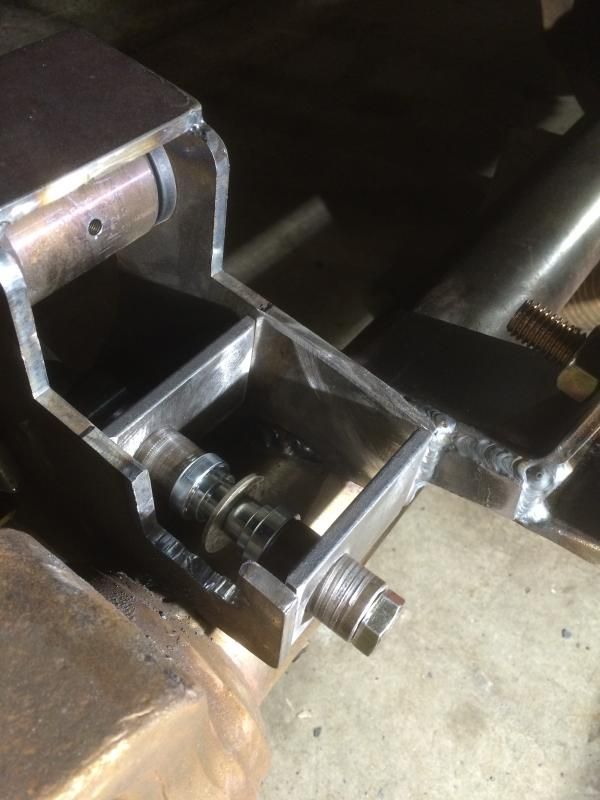

Checking clearances after trimming the crossmember a little more. This is full compression on the passenger side

It is hard to tell here but the bar would hit the crossmember just before the oil pan. I plan on setting the bump stops to give me about .5" of clearance at this juncture

At full compression the tires are perfectly stuffed in the wheel wells

This is at full compression on the passenger side and about 7" from full droop on the drivers side

This is about one inch from full droop on both sides

While I am waiting for my coilovers to get here I will take the manual hubs off the d50 and anything else I might need from it so I can take it to the scrap yard and get it out of my garage. I also need to bolt the trans crossmember back together and pick up some extended brake lines for the front. If everything goes well I will have the front pretty close to wrapped up by the end of this holiday weekend.

[/URL

[/URL

[/URL

[/URL