amgvr4

Adventurer

Underdrive;

Thanks for the compliments. I ended up cutting the slot larger similar to what you suggested and added some gussets as well. Great minds think alike!

I was able to work on the towers today. It took a lot of thinking but I am pretty sure how I want to proceed. I toyed with several ideas including shock hoops but in the end I wanted something that will be possible to remove in case something ever happens to this truck or I need to make changes to them.

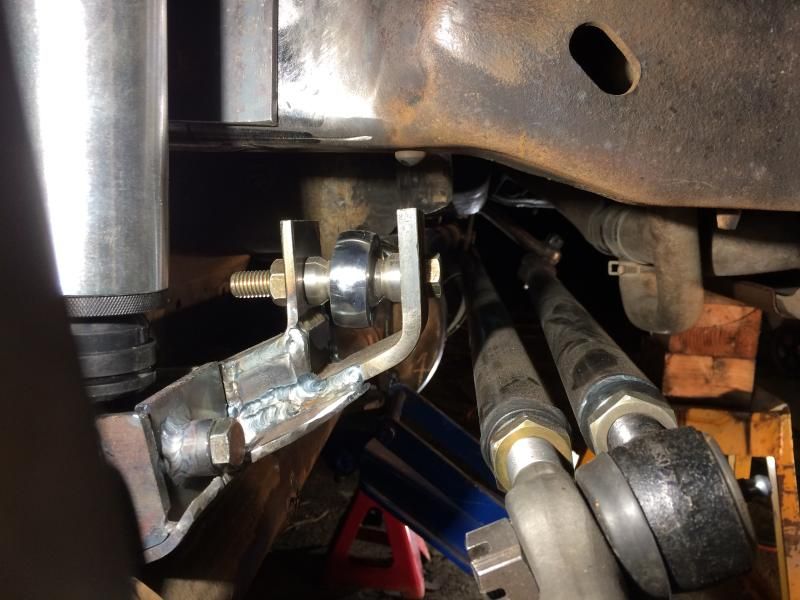

I added a gusset to the track bar/radius arm mount to add more lateral strength

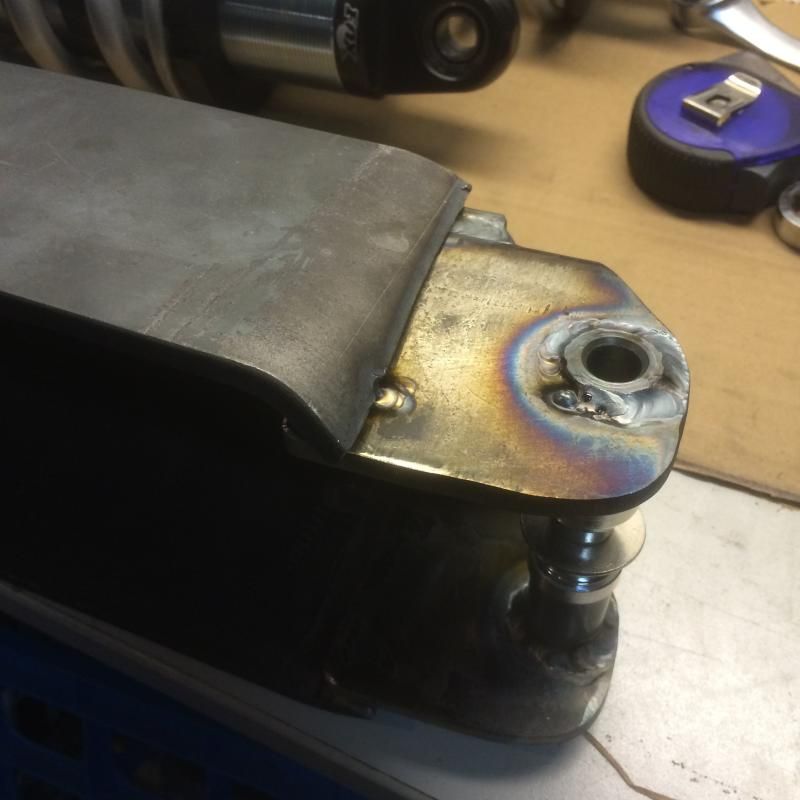

I started the towers by bending some 4"x.250 plate into a 3" channel and then drilling the holes for the weld in spacers

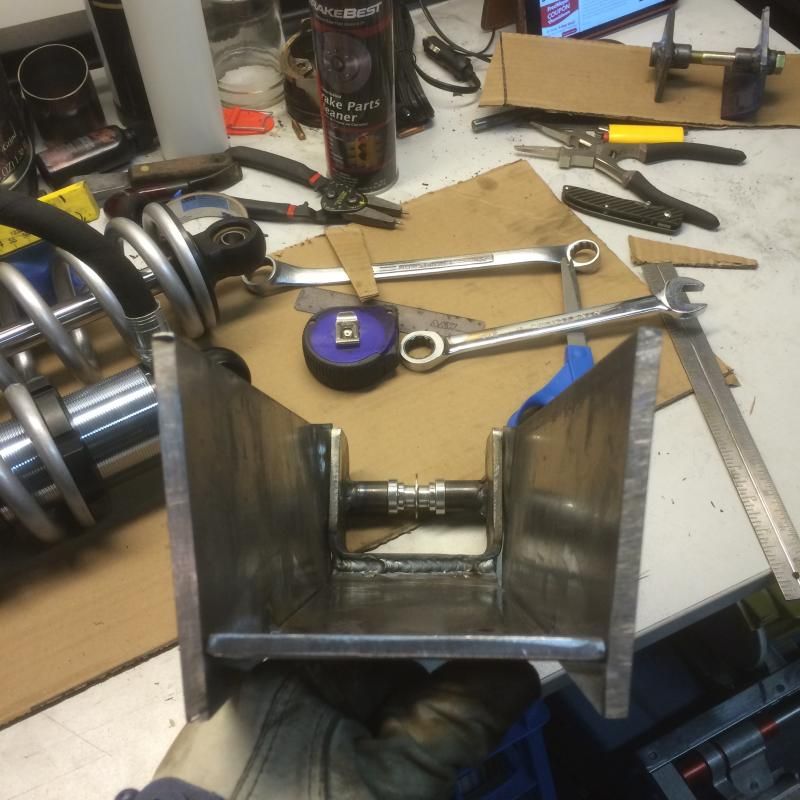

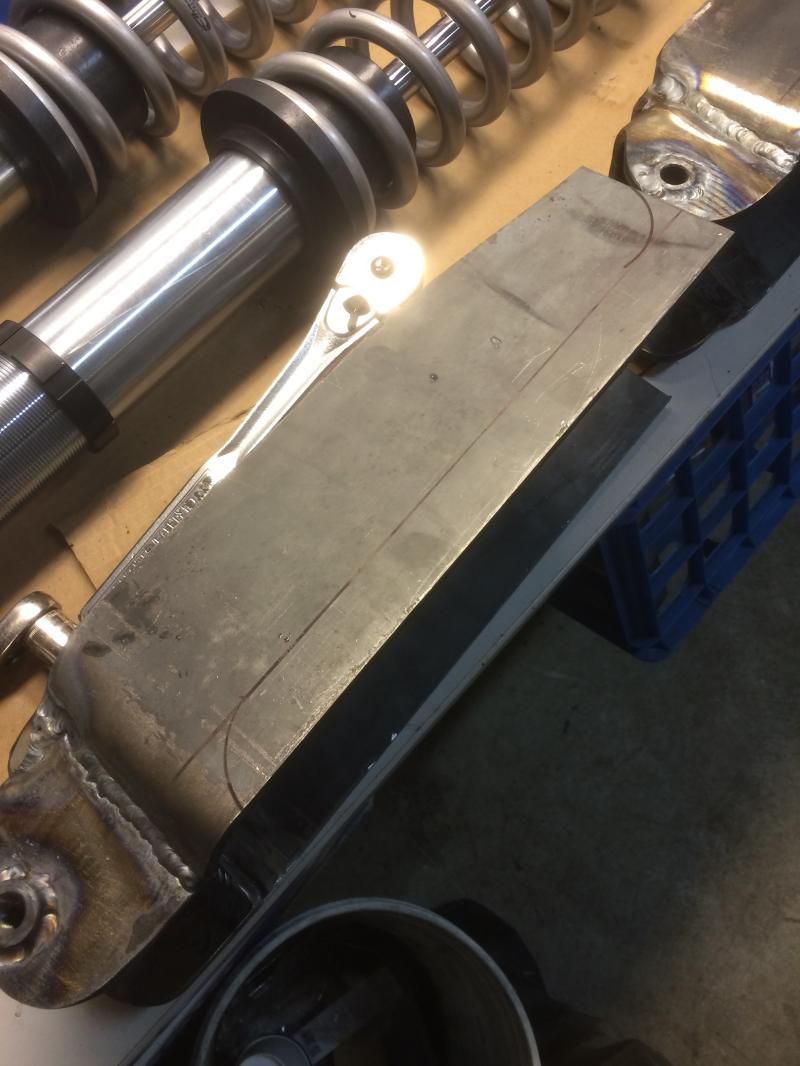

Then I used a 16" long section of 4x.250 plate to make the back bone of the towers. I bent it to allow for the bump in the drivers side and to space the coilover properly. Both tacked together

I drilled two holes in it to be able to bolt it on for the fitting process. As soon as it is all done and fully welded I will weld it to the frame.

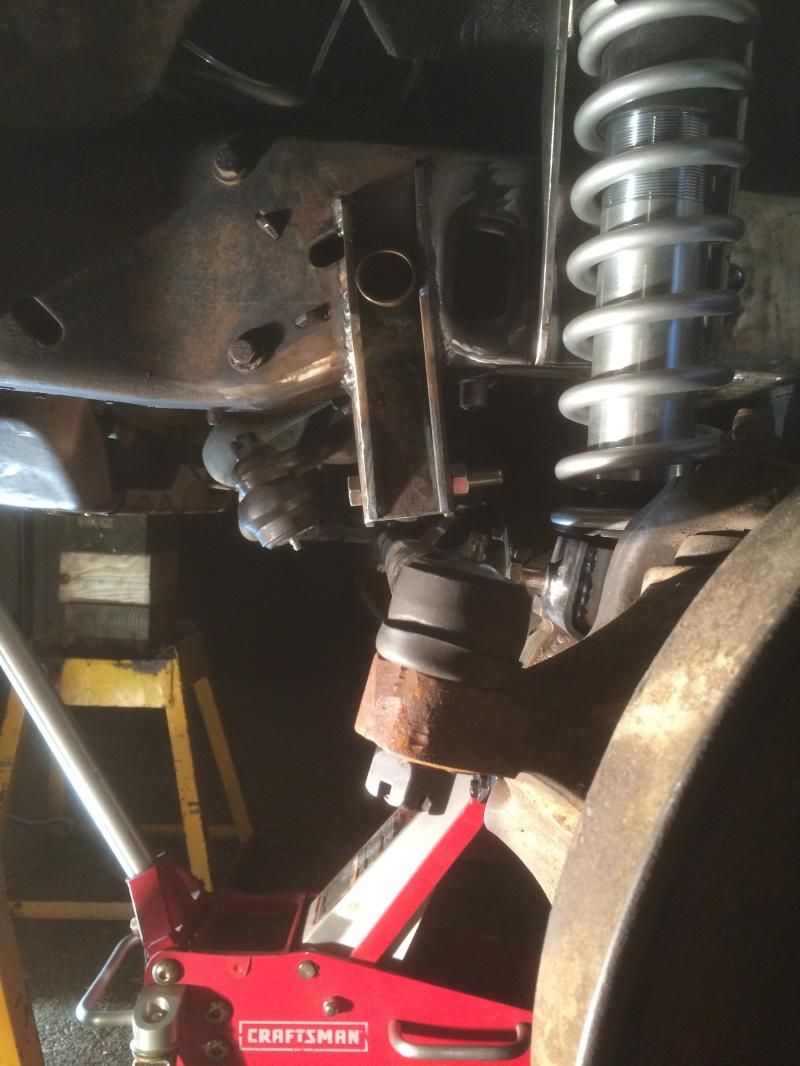

The lower mount

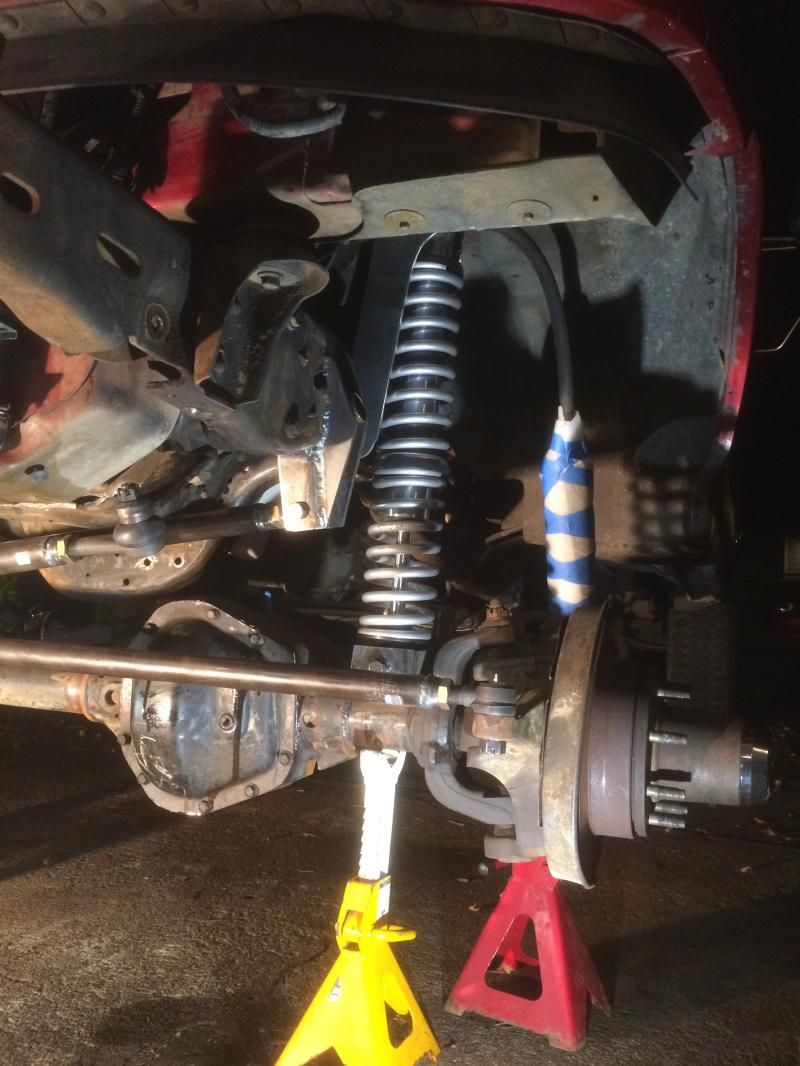

At full compression

I didn't pay enough attention to the overall height of the tower vs the centerline of the shock bolt so my ride hight is too tall. I measured properly when sizing my shocks, but the bracket ended up pretty large so it hits the inner fender well and does not allow the tower to be as tall as it needs to be. The axle is at least 1" too low compared to where I want it at full compression.

I had originally planned on about a half inch of clearance between the track bar and crossmember. It's about 1 3/4" now.

This is full droop

So I need to trim down the top mount and raise the height of the tower at least 1" to have the ride hight I am looking for. Once I have the passenger side where I want it I will get the drivers side to the same point and fully cycle the axle to make sure everything clears and works as it should. Then I will box in the towers and make the bump stop and remote reservoir mounts. Getting close!

Thanks for the compliments. I ended up cutting the slot larger similar to what you suggested and added some gussets as well. Great minds think alike!

I was able to work on the towers today. It took a lot of thinking but I am pretty sure how I want to proceed. I toyed with several ideas including shock hoops but in the end I wanted something that will be possible to remove in case something ever happens to this truck or I need to make changes to them.

I added a gusset to the track bar/radius arm mount to add more lateral strength

I started the towers by bending some 4"x.250 plate into a 3" channel and then drilling the holes for the weld in spacers

Then I used a 16" long section of 4x.250 plate to make the back bone of the towers. I bent it to allow for the bump in the drivers side and to space the coilover properly. Both tacked together

I drilled two holes in it to be able to bolt it on for the fitting process. As soon as it is all done and fully welded I will weld it to the frame.

The lower mount

At full compression

I didn't pay enough attention to the overall height of the tower vs the centerline of the shock bolt so my ride hight is too tall. I measured properly when sizing my shocks, but the bracket ended up pretty large so it hits the inner fender well and does not allow the tower to be as tall as it needs to be. The axle is at least 1" too low compared to where I want it at full compression.

I had originally planned on about a half inch of clearance between the track bar and crossmember. It's about 1 3/4" now.

This is full droop

So I need to trim down the top mount and raise the height of the tower at least 1" to have the ride hight I am looking for. Once I have the passenger side where I want it I will get the drivers side to the same point and fully cycle the axle to make sure everything clears and works as it should. Then I will box in the towers and make the bump stop and remote reservoir mounts. Getting close!