amgvr4

Adventurer

Sunday

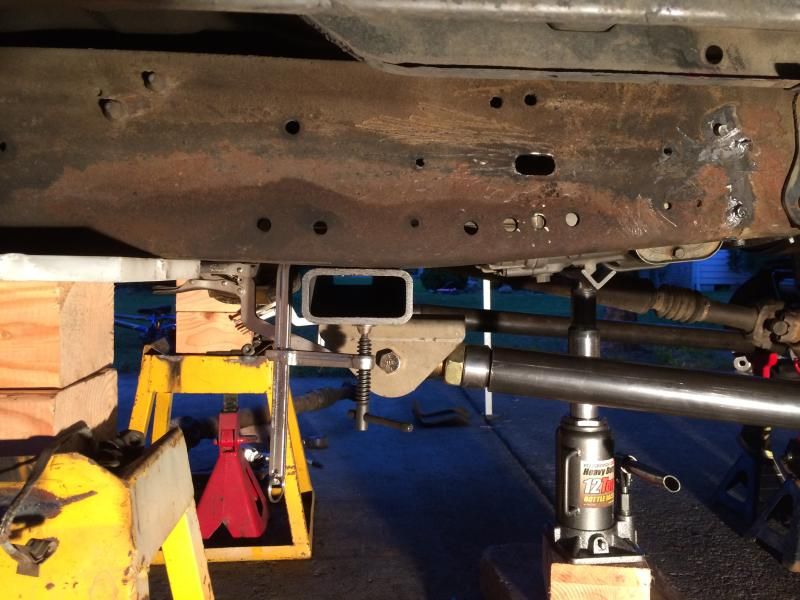

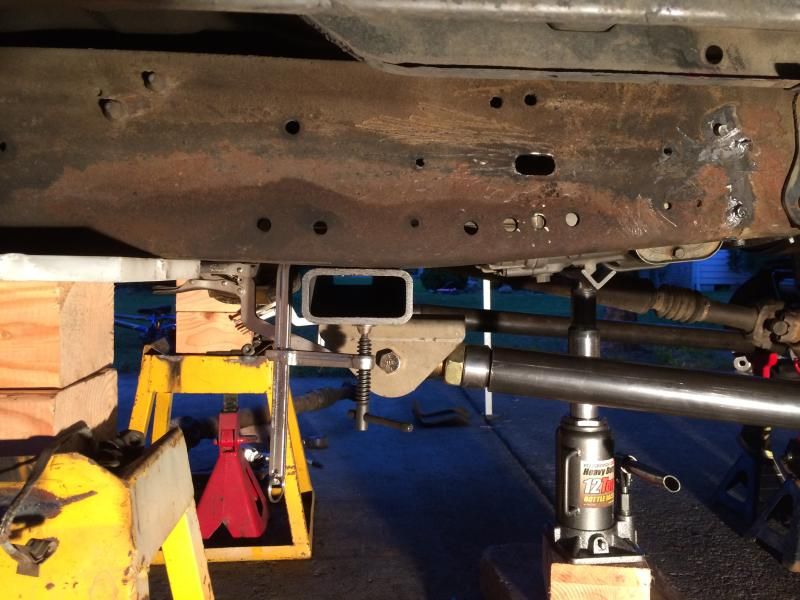

Not a lot done today. Only had a few hours so I spent it trying to nail down the x-member and radius arm mounts. I came up with several options.

First option and most difficult is to make a new x-member and mount the jonny joints inboard on it

Pros;

Best articulation

Best turning radius

Stronger mounting point for arms and much simpler x-member than factory

Cons;

Joints are 2" lower for the worst ground clearance.

More things to make

Front drive shaft will be tough to clear the cross beam with full articulation

Second option and easiest, shorten the radius arms to 34" and mount them to the frame.

Pros;

Easiest by far

Cons;

Reduced turning radius, possibly worse than the leafs

Shorter arms= less flex

Third and probably my favorite is to keep the arms at 39" and inboard them slightly with frame pads just behind the factory x-member.

Pros;

Less fab work

Good articulation

A little better turning radius than leafs

Cons;

Not what I was hoping for on turning radius or articulation

Not as strong of a mounting point

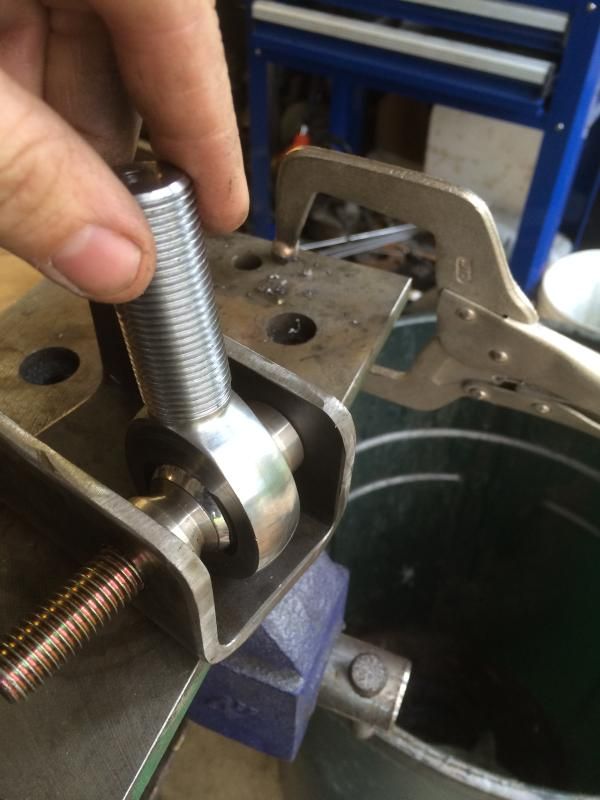

I also got a chance to test out the reinforcement I added to the engine crossmember chop I did. It supports the full weight of the front of the truck great!

Not a lot done today. Only had a few hours so I spent it trying to nail down the x-member and radius arm mounts. I came up with several options.

First option and most difficult is to make a new x-member and mount the jonny joints inboard on it

Pros;

Best articulation

Best turning radius

Stronger mounting point for arms and much simpler x-member than factory

Cons;

Joints are 2" lower for the worst ground clearance.

More things to make

Front drive shaft will be tough to clear the cross beam with full articulation

Second option and easiest, shorten the radius arms to 34" and mount them to the frame.

Pros;

Easiest by far

Cons;

Reduced turning radius, possibly worse than the leafs

Shorter arms= less flex

Third and probably my favorite is to keep the arms at 39" and inboard them slightly with frame pads just behind the factory x-member.

Pros;

Less fab work

Good articulation

A little better turning radius than leafs

Cons;

Not what I was hoping for on turning radius or articulation

Not as strong of a mounting point

I also got a chance to test out the reinforcement I added to the engine crossmember chop I did. It supports the full weight of the front of the truck great!

[/URL

[/URL

[/URL

[/URL [/URL

[/URL

[/URL

[/URL