Well, I have been busy with the Jeep and I am falling behind on the build page so here we go...

1) Installed Midland 1001 LWX CB radio. You may have noticed the 4' Firestik on the carrier that goes with it. I installed it above the rearview mirror using a very nice little bracket from Strike Force Zebra. It mounts under the footman loop, and puts the radio in a perfect position just above the mirror so as not to interfere.

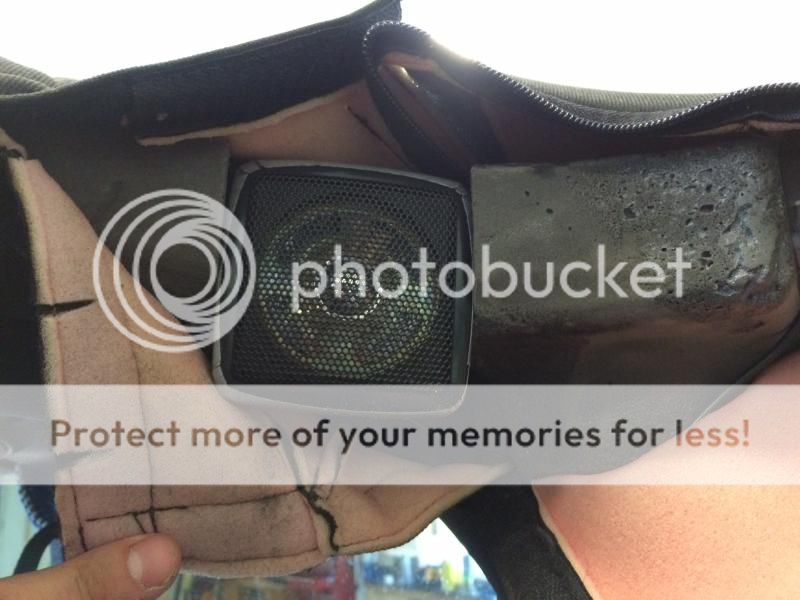

2) With the CB install, I added a 5 watt compact external speaker, and installed it in the roll bar foam / under the padding on the driver's side. I used a fein tool to cut the foam out which was very accurate and it cut like a hot knife through butter. I like this position a lot for the speaker, as it is right in my ear an easy to hear detail.

://s695.photobucket.com/user/coloram/media/IMG_0268_1.jpg.html]

[/URL]

3) I finished installing accessory switches inside the Jeep. I determined that I needed 3 switches for the things that would be installed, and found that there is an area in the center console that has clearance for 3 carling rockers between the t-case and transmission shifters. This is what I came up with:

The frontmost switch is for the ARB compressor. I just added the other two, which I got to match the blue light of the ARB switch from ottratw.com. One is "Driving Lights" for my future off-road lights, and one is "Rock Lights" for a set of LED undercarriage and LED rear-Facing floods I have ready to go. More on that to come... There is a channel between the two shifters deep enough to accomodate the switch bodies and wiring, and then it is easy to run wire through the front of the console and through the dash.

I wired everything to my own DIY "S-POD". I found a nice sealed plastic housing at my local auto parts store, which I piggybacked to the lid of the factory fuse box. I then added a 6-way fuse block from NAPA, and will have room for the lighting relays to all tuck into a nice tight package. I left enough wire for the factory fuse lid to swing open easily.

4) In one of the above photos, you can also see a Tekonisha P2 trailer brake controller, which I also just finished the install on. I fabricated my own off-road trailer last year, and saw numerous advantages to having trailer brakes in that setup. (Added braking in the mountains, added braking on steep descents, ability to drag trailer brakes and straighten vehicle/trailer, etc.) I installed them on the axle assembly for my trailer and now have the right component and wiring to actuate them properly. I will be in the process of doing a build page for my little trailer as well, but haven't made it that far yet. You can see it in a photo on the first page...

5) The last thing I am currently wrapping up is a full sound-insulation treatment to the floor and doors. When I did this exact process in my Tacoma, it made a HUGE difference in NVH levels and overall comfort inside the vehicle... and I do mean HUGE. I initially performed the modification to cut down the tire noise, but discovered a very interesting by-product of doing this: it felt like I had upgraded the suspension on dirt roads! On washboard / rough roads the resonating sound in the body was reduced, and it made things seem "smoother" just because of the decrease in sound. From then on I swore I would do this to every off-road rig I had henceforth, and here we are.

SO the procedure... The two products are Peel and Seal aluminum sealant tape from Lowes, followed by a layer of 1/8" Frost King duct insulation from Home Depot. There is a lot of internet chatter about using this method, but in my own experience it works VERY well, does not smell at all, and adhesion remains very good for years if installed properly. It is loads less expensive than using the brand name sound dampener products like Dynamat.

After stripping everything down to bare floor, I install 1-2 layers of the Peel and Seal. This is a pressure adhesive, so I use the back of a plastic screwdriver handle and rub it down with some elbow grease into EVERY NOOK AND CRANNY to get it to stick down properly. This layer will only do it's job if it is adhered to the metal 100%. We are adding mass to the sheet metal, which in-turn lowers the resonating frequency down. The lower the resonating frequency, the quieter your vehicle will be. Also, the foil facing of the Peel and Seal acts like a second layer of sheet metal. Sound "echoes" off the foil and the floor metal, and gets stuck in the butyl rubber layer where it is reduced.

Then, I add a layer of the duct insulation product using 3M high strength spray adhesive. This layer is just for more sound absorbtion and isolation, so the adhesion is not quite as critical. I do roll every piece out with a small wallpaper seam roller to make sure it is adhered well.

I cut around all the drain holes and any other penetrations / hardware so as not to impact any service work in the future. I will do everything that is covered by carpet this way. For the doors, my options were very limited for installing the Peel and Seal, but I put a few pieces on the interior plastic panel that did not interfere with any of the components on the door. What worked great, however, was bonding a layer of the duct insulation to the inside of the plastic panel with spray adhesive. This ended up working perfect, with zero interference to the way the piece fit back on the door.

Still working on the sound damening procedure, but i will post an update when I take it on a test-drive after. I am not expecting it to be quite as stark a difference with the soft top, but I still feel strongly that this will help in many ways with interior comfort.