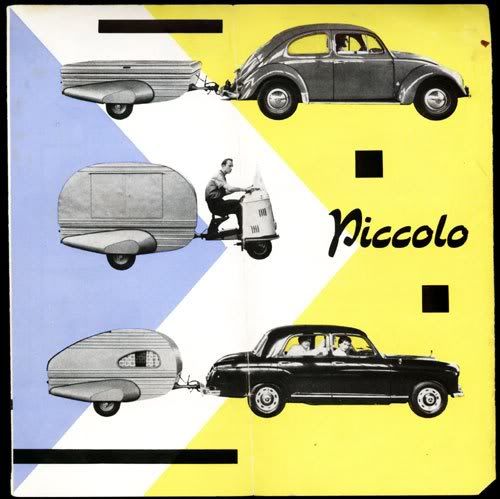

I have worked a sweet deal .Will be building two trailers. The first one will be a sport dux light. To me it looks like a sporty economy 1958 Scotty Cento trailer.Number two will be a be a Benroy style.

The deal is I build the two & take lots of pictures. Pick the one I want .Have the manufacturer pick up the other . Reimburse the cost for the one they take back.

On the one I keep I get reimburse For the fiberglass component kit and the trailer base. If I keep the two trailers I get reimburse for the Sport dux light fiberglass component kit. They want the pictures for doing a Building Guide for there Modular fiberglass component kit.

I will start with one kit the dux light using Andrew Gibbens ULTRALIGHT CHASSIS http://www.angib.pwp.blueyonder.co.uk/teardrop/tear57.htm[/URL] .

I will be building these in my dad's garage which is a hour drive . By doing two at a time .I will not drive there just to do a hour are so of work just to go home

The deal is I build the two & take lots of pictures. Pick the one I want .Have the manufacturer pick up the other . Reimburse the cost for the one they take back.

On the one I keep I get reimburse For the fiberglass component kit and the trailer base. If I keep the two trailers I get reimburse for the Sport dux light fiberglass component kit. They want the pictures for doing a Building Guide for there Modular fiberglass component kit.

I will start with one kit the dux light using Andrew Gibbens ULTRALIGHT CHASSIS http://www.angib.pwp.blueyonder.co.uk/teardrop/tear57.htm[/URL] .

I will be building these in my dad's garage which is a hour drive . By doing two at a time .I will not drive there just to do a hour are so of work just to go home