Lord Al Sorna

Harebrained Scheming

Greetings fellow Expo members! I am throwing up a build page for my latest undertaking, and that is to convert a 5x8 Wells Cargo utility trailer into an off-road capable camp trailer.

Previously, I had built a sweet little off-road trailer modeled loosely off of some of the Adventure Trailers offerings. This thing went everywhere with us for two years without missing a beat, but over that time the wish list began to become more clear and change a little from what our trailer and RTT offered. My old trailer has found a new home with some of our good friends, who could not be more thrilled about it. Here is a pic of one our her last outings with us:

The decision to make this change came about in a few areas we saw that would improve our camping enjoyment even more than the previous setup. First, we wanted our two dogs to be in the same area as we were at night. With the RTT, they had to sleep in the back of my Jeep. Usually this worked ok, but it is a change that we both had strong preference for. Secondly, we wanted a more comfortable spot to sleep and spend time when the weather was less than picturesque. High winds, rain, and snow will have a lot less impact on our travel plans and enjoyment by making this transition. Lastly, we wanted a quieter and more private arrangement for the times that *god forbid* we camp in campgrounds and closer to civilization. We try to avoid doing this when possible, but there are plenty of reasons to do it on some trips. I want to be happily tucked in a sound insulated foam box when people around me are making noise, running generators, and generally detracting from my desire to experience peaceful surroundings.

So I started scratching around and thinking about how to do a trailer with hard sides. I looked at building my own teardrop from scratch, tearing apart my old trailer and re-building from the frame up, or buying a teardrop from a place like AT or So-Cal trailers. Buying a trailer was out because for me, what you get is not worth the price tag. I found a buyer for my old trailer as it was setup, so that was out. I then decided that the most efficient way to get what I had in my mind out on the road was to start with a common utility trailer. This would allow me to modify an existing assembly over starting over again from scratch, saving significant manhours in the overall build time.

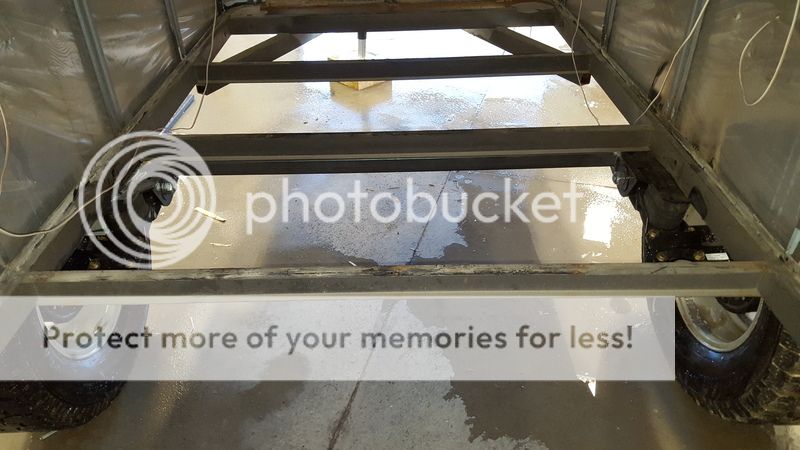

So... The candidate for surgery was found:

2003 Wells Cargo. Desirable features for my purposes were 1) The bent up-sweep in the front frame rails for added clearance and better alignment for the raised hitch modification I did to my Jeep. 2) The double barn door config in the rear (vs. the drop-down ramp a lot of these come with). The combination of these two features and a decent price made it my winner.

And now we transform it from a tired, rusty construction workhorse to a plush and luxurious backcountry condo!

Previously, I had built a sweet little off-road trailer modeled loosely off of some of the Adventure Trailers offerings. This thing went everywhere with us for two years without missing a beat, but over that time the wish list began to become more clear and change a little from what our trailer and RTT offered. My old trailer has found a new home with some of our good friends, who could not be more thrilled about it. Here is a pic of one our her last outings with us:

The decision to make this change came about in a few areas we saw that would improve our camping enjoyment even more than the previous setup. First, we wanted our two dogs to be in the same area as we were at night. With the RTT, they had to sleep in the back of my Jeep. Usually this worked ok, but it is a change that we both had strong preference for. Secondly, we wanted a more comfortable spot to sleep and spend time when the weather was less than picturesque. High winds, rain, and snow will have a lot less impact on our travel plans and enjoyment by making this transition. Lastly, we wanted a quieter and more private arrangement for the times that *god forbid* we camp in campgrounds and closer to civilization. We try to avoid doing this when possible, but there are plenty of reasons to do it on some trips. I want to be happily tucked in a sound insulated foam box when people around me are making noise, running generators, and generally detracting from my desire to experience peaceful surroundings.

So I started scratching around and thinking about how to do a trailer with hard sides. I looked at building my own teardrop from scratch, tearing apart my old trailer and re-building from the frame up, or buying a teardrop from a place like AT or So-Cal trailers. Buying a trailer was out because for me, what you get is not worth the price tag. I found a buyer for my old trailer as it was setup, so that was out. I then decided that the most efficient way to get what I had in my mind out on the road was to start with a common utility trailer. This would allow me to modify an existing assembly over starting over again from scratch, saving significant manhours in the overall build time.

So... The candidate for surgery was found:

2003 Wells Cargo. Desirable features for my purposes were 1) The bent up-sweep in the front frame rails for added clearance and better alignment for the raised hitch modification I did to my Jeep. 2) The double barn door config in the rear (vs. the drop-down ramp a lot of these come with). The combination of these two features and a decent price made it my winner.

And now we transform it from a tired, rusty construction workhorse to a plush and luxurious backcountry condo!