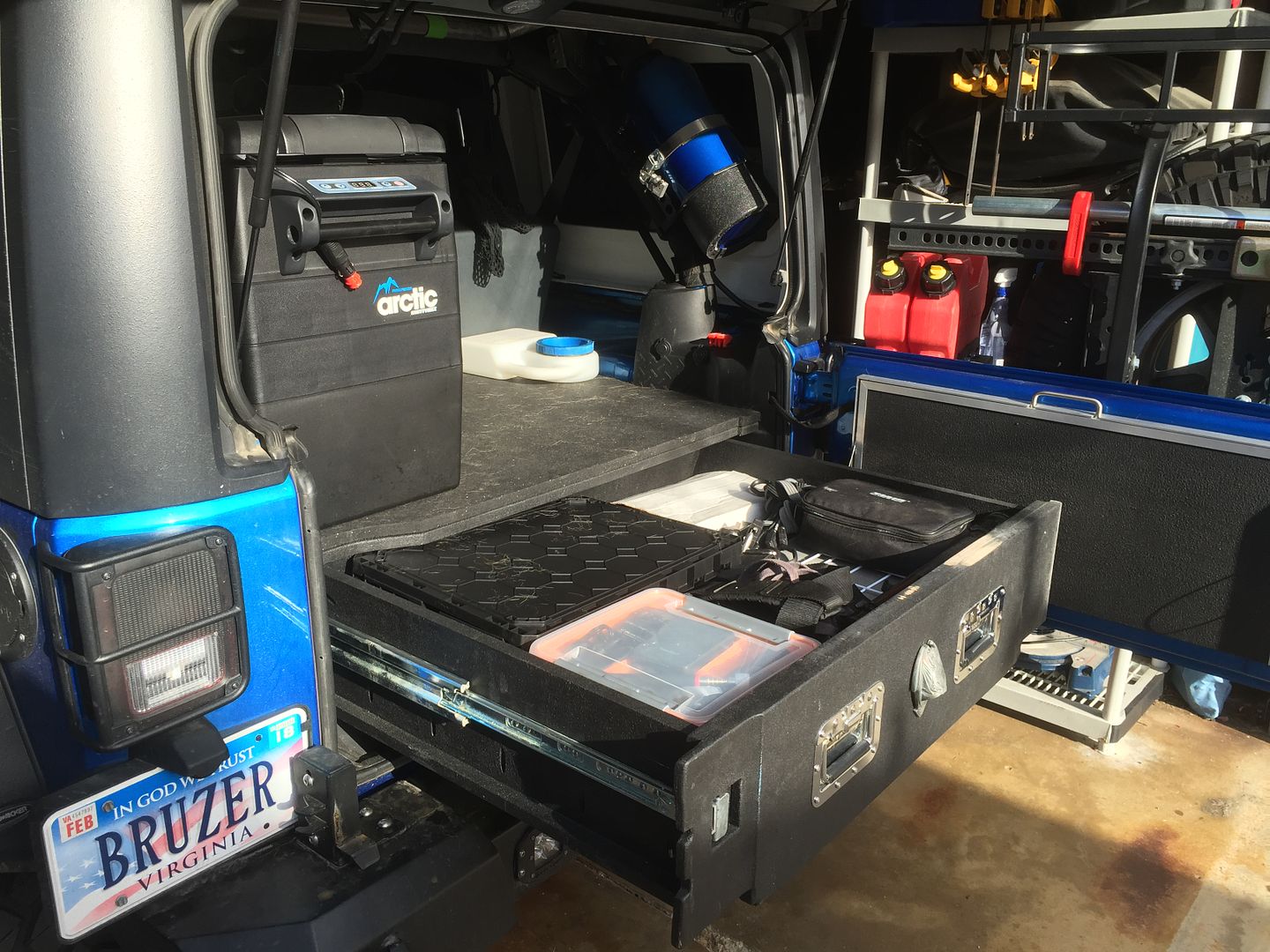

I have a very limited amount of space in the back of my JKU. It's currently equipped with a custom drawer system, frontrunner water tank and a Smittybilt Arctic fridge. None of the pre-made fridge slides I've found fit my limited space (~24") front to back, leaving me with the option of building my own.

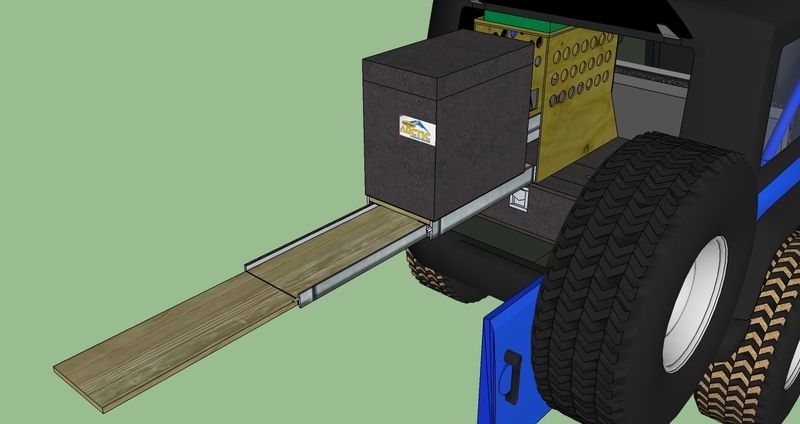

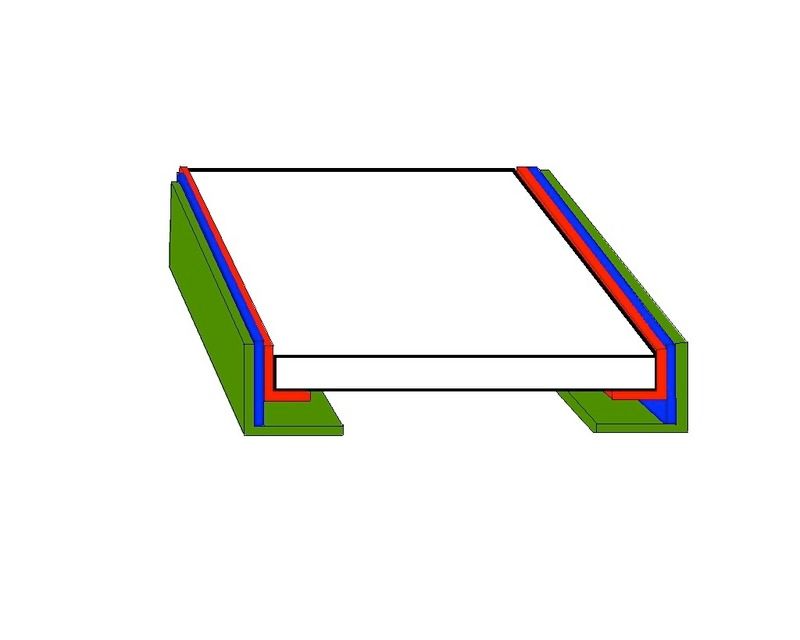

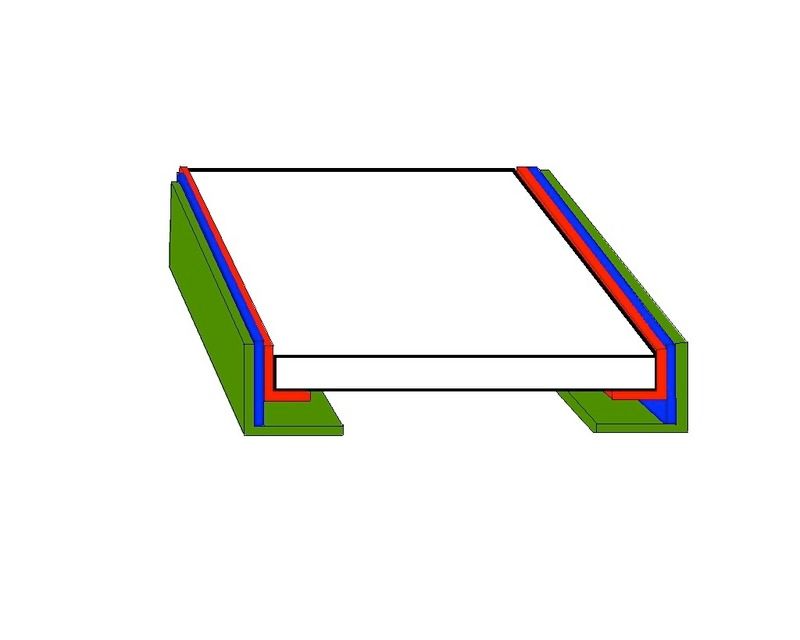

So far my plan is simple. 4 pieces of steel angle iron, 1/2" birch and 2x 24" Accuride 9308 slides. The angle iron would sandwich the slides(Blue), one angle iron(Green) connects the slide to the existing drawer slides and the other angle iron(red) connects the slide to the 1/2 birch slider top.

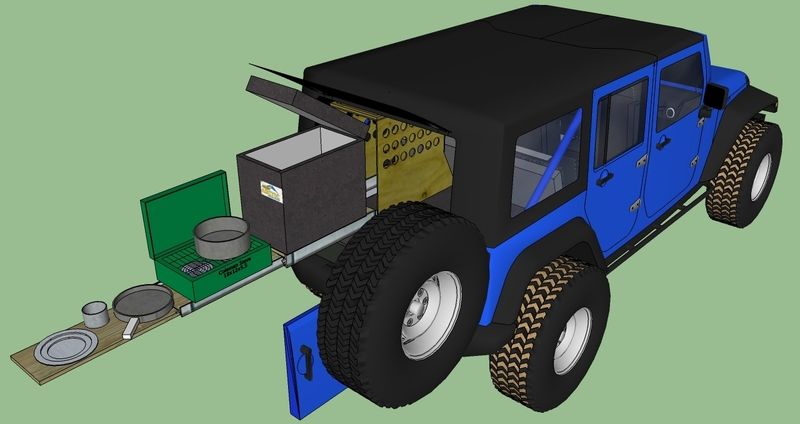

I may incorporate a tilting feature, we'll see. I'm looking for ideas, so show me what you've done!

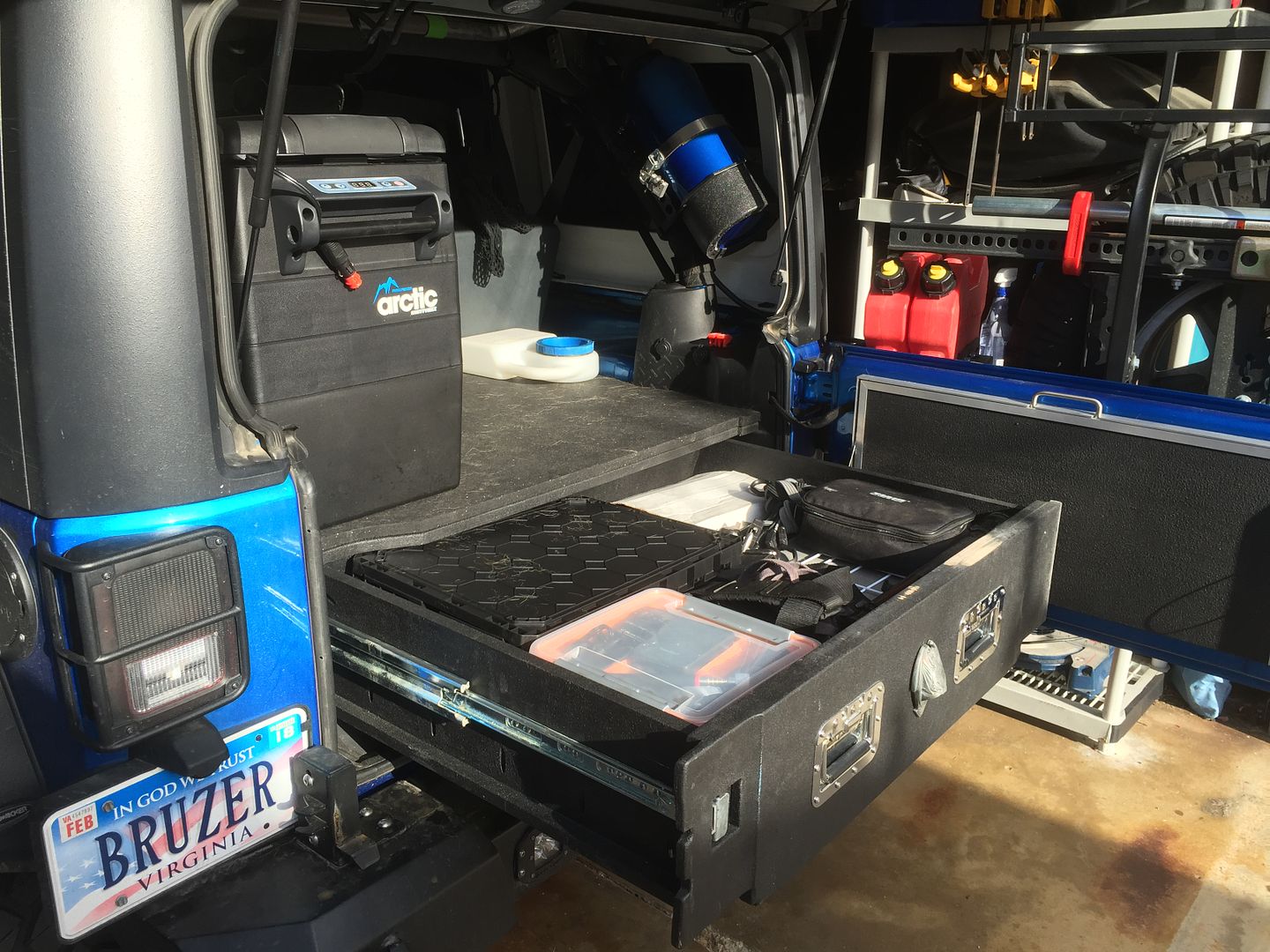

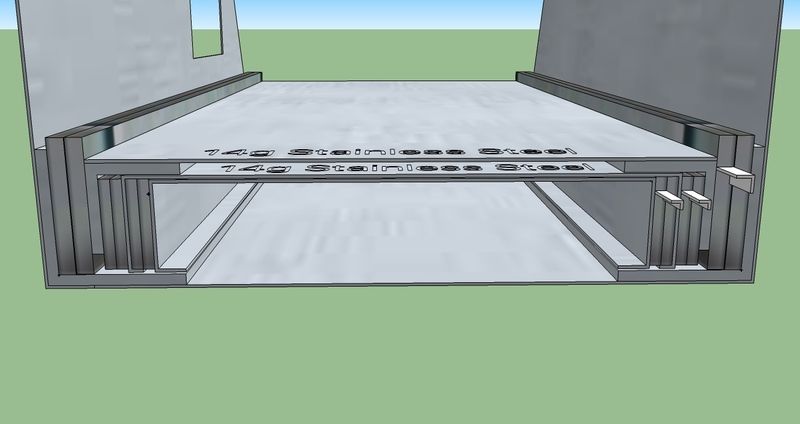

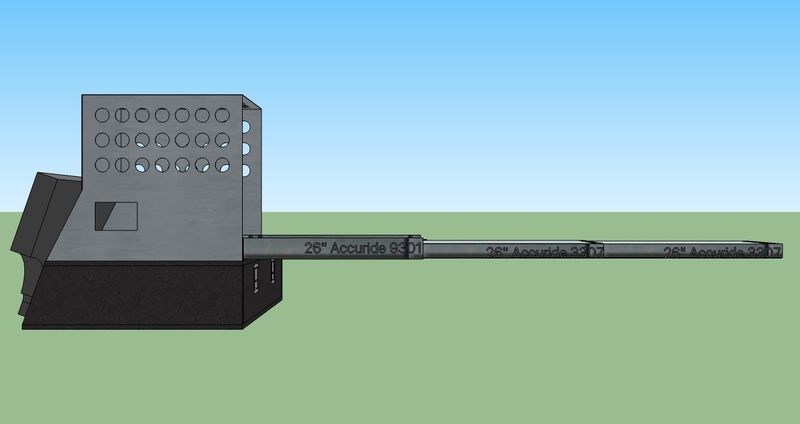

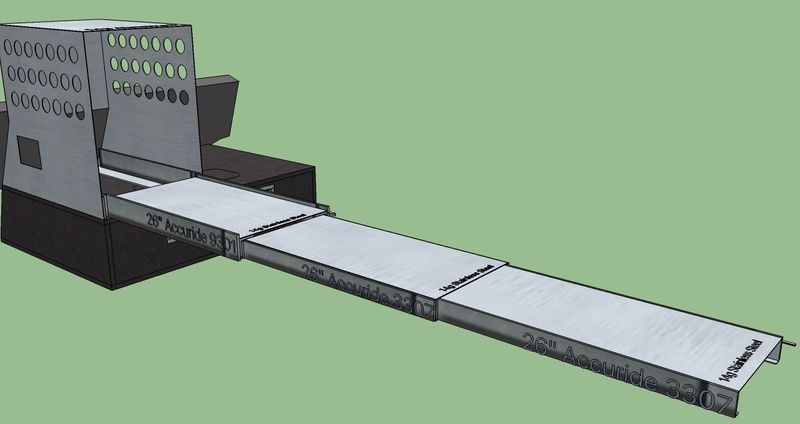

Current set up.

So far my plan is simple. 4 pieces of steel angle iron, 1/2" birch and 2x 24" Accuride 9308 slides. The angle iron would sandwich the slides(Blue), one angle iron(Green) connects the slide to the existing drawer slides and the other angle iron(red) connects the slide to the 1/2 birch slider top.

I may incorporate a tilting feature, we'll see. I'm looking for ideas, so show me what you've done!

Current set up.