Weekend update, 'who's dumb idea was this'.....

This is where I ended up after a few more days of playing with tube. One of my pet peeves with cages is that there is typically a lot of wasted space, specifically over the top of the spreaders. I am trying to combine a lot of different features with my 'cage' and that makes things a more challenging than I want to admit sometimes. I try and stay ahead of the curve and plan ahead....but dang this one tube kicked by butt all day long.

The top of the FJ40 windshield has a gentle curve that I wanted the windshield spreader bar to follow. Since that radius is so large, I needed to roll that section of the tube, but also give myself enough straight at the ends to be able to add a 45 degree drawn bend to each end AFTER the rolling process. In order to facilitate that I had to leave a 4" long straight section between the rolled bend and the start of the drawn bend. That 4" is the minimum distance on my bender from the start of bend to the retaining strap on my Pro-Tools 105, 1.5x4.5CLR die. It also just happens to be just about the exact distance between the rollers on a Harbor Freight tube roller.

I guess I need to take a step back for a minute to explain the setup...

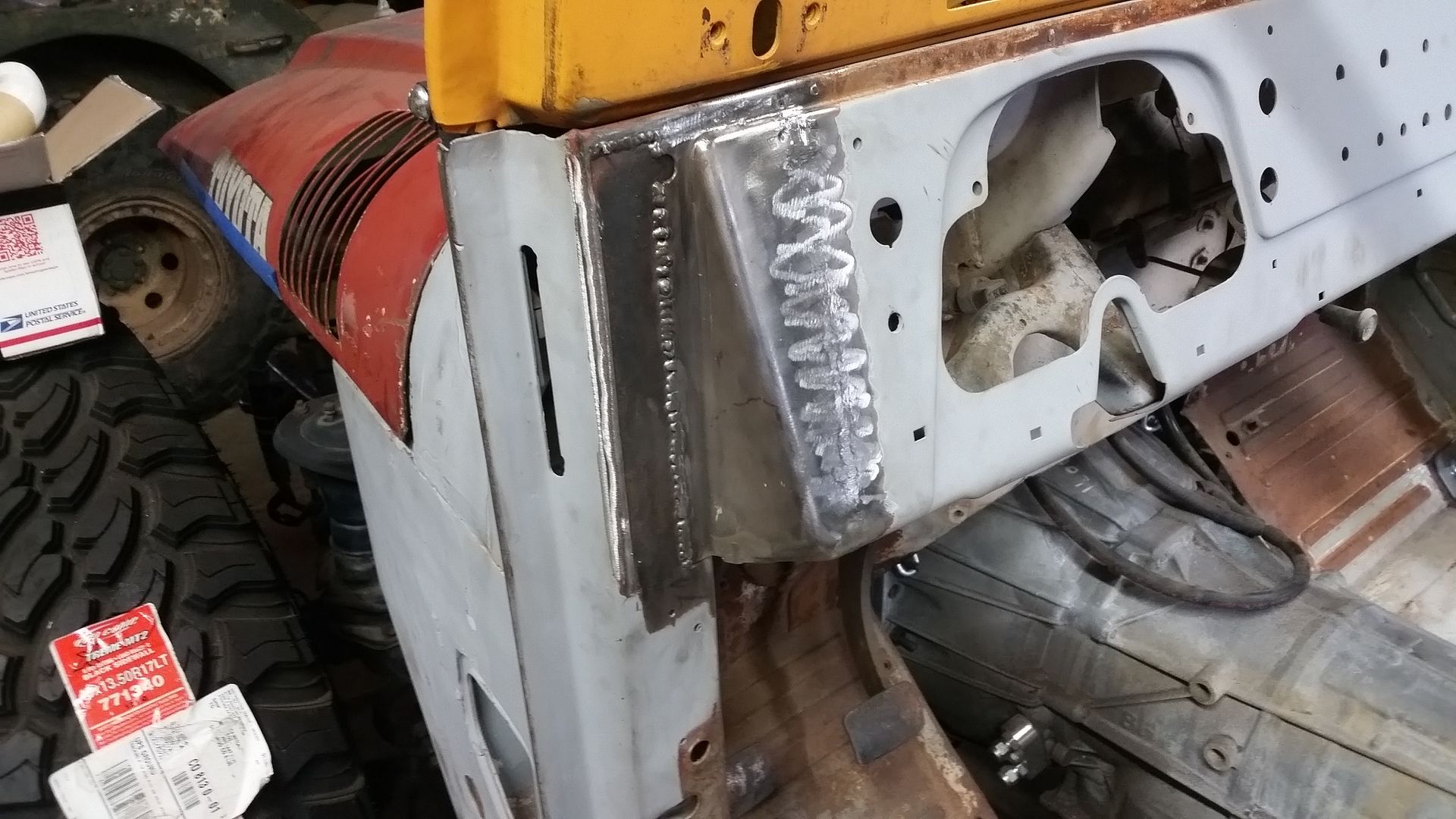

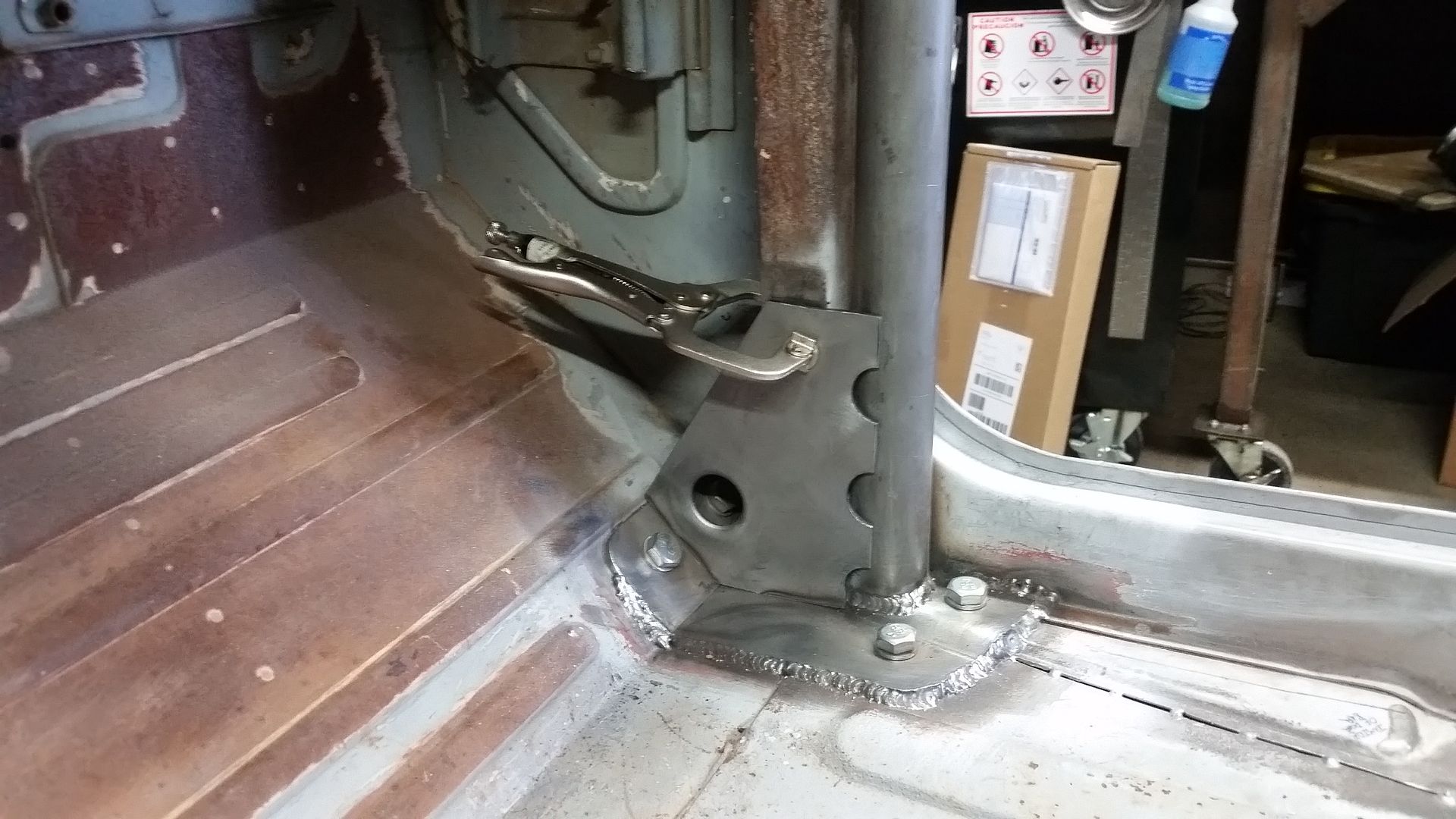

I needed to finish off the A-pillar down tube for the drivers side. That wasn't a big deal. I actually got pretty lucky and it went much quicker than the 1st one on the passenger side.

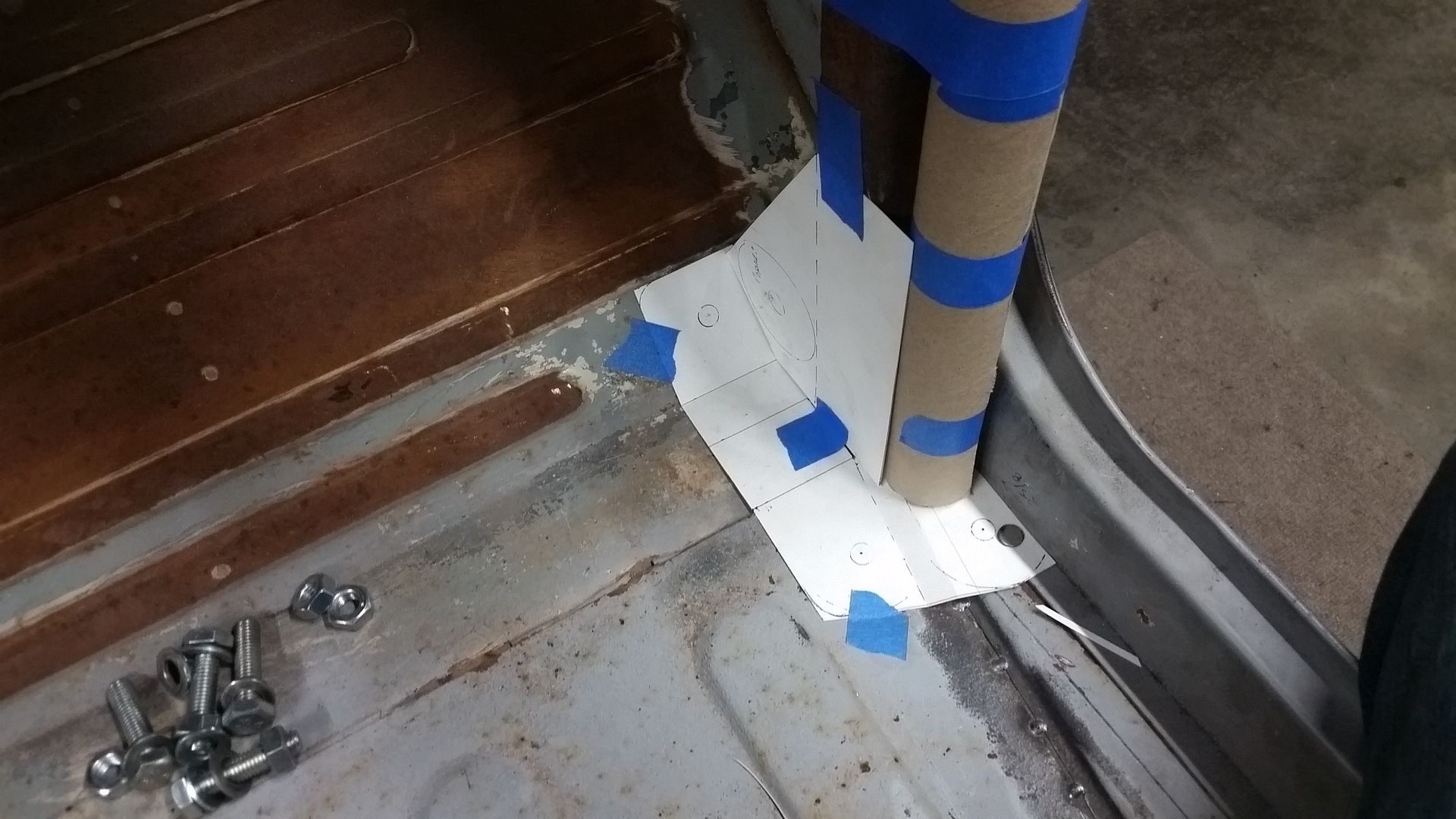

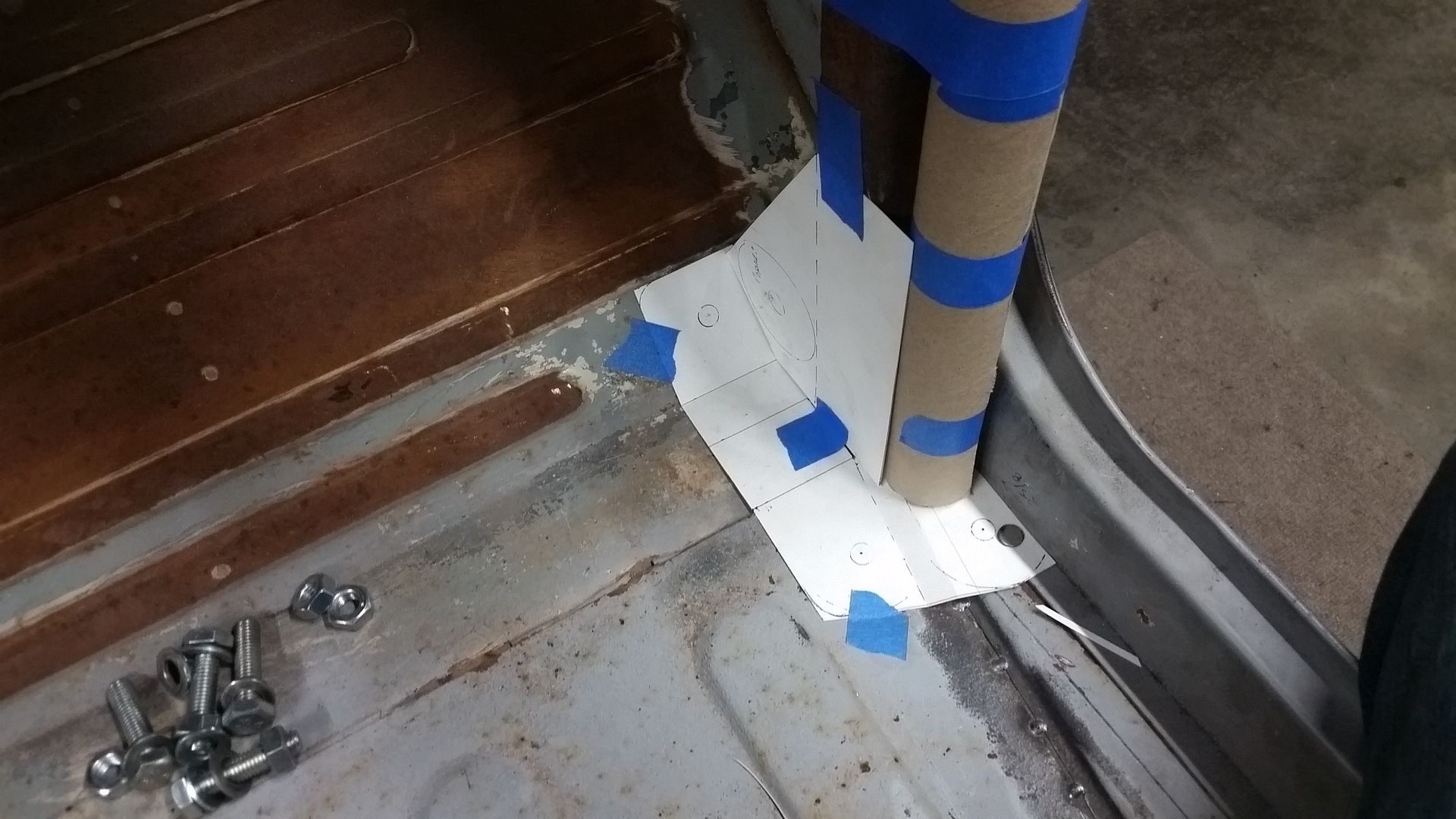

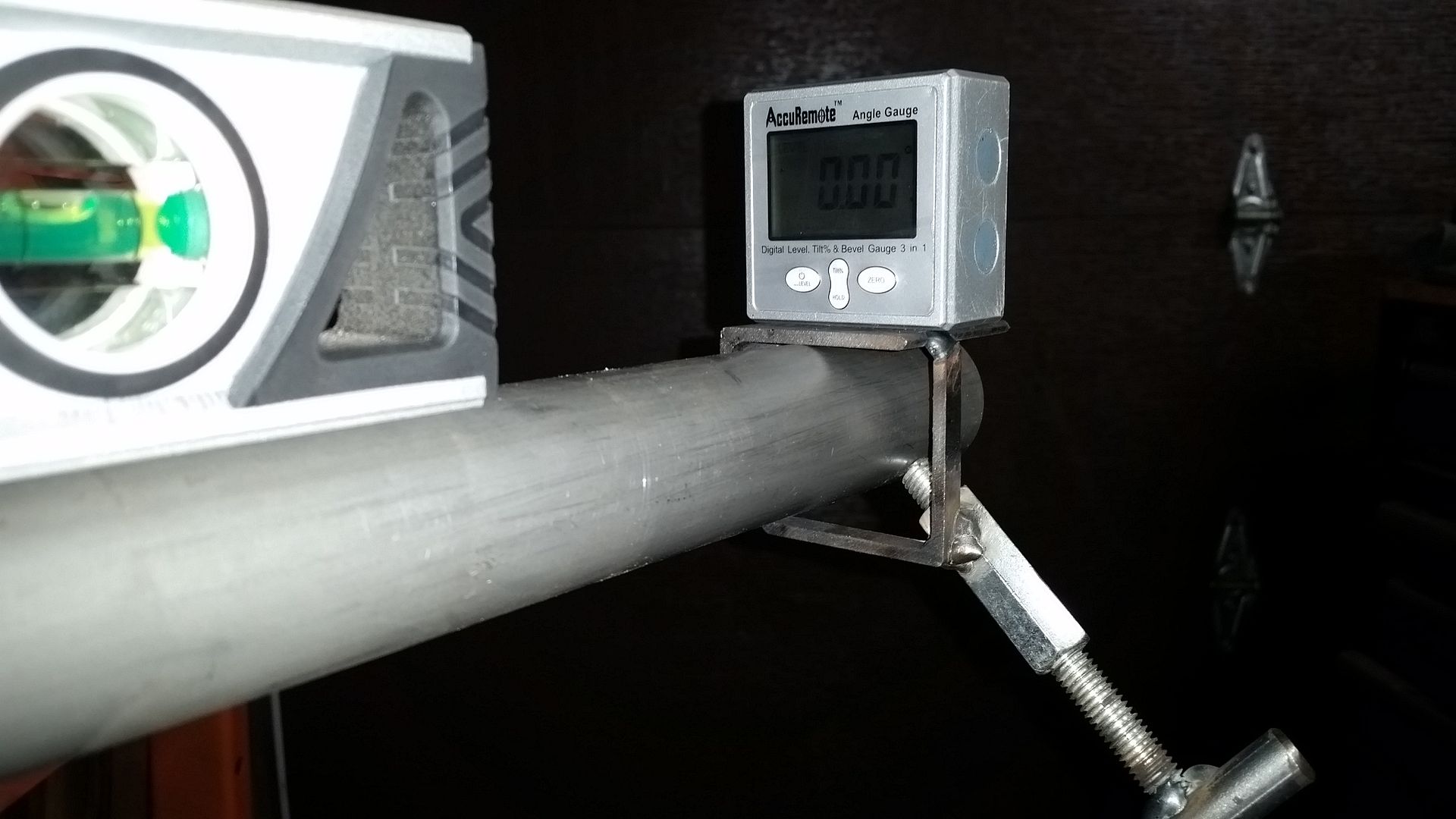

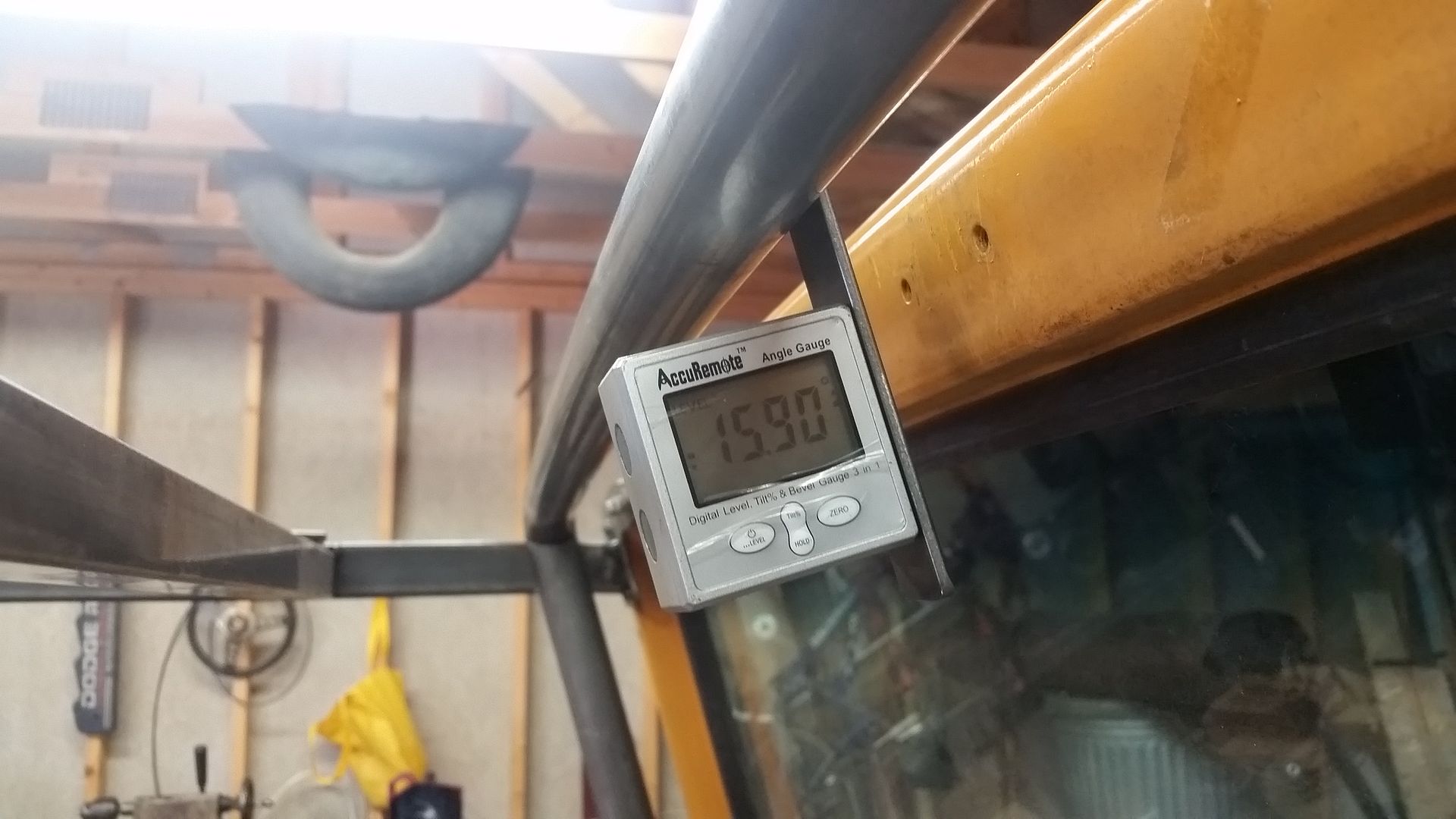

Once I had both A-pillars done, I could build a 'plane of bend' jig that would allow me to trim the windshield spreader bar without the A-pillar tubes in place in a known reference position. I also wanted the windshield spreader bar bend plane to be leaned back at the same angle as the windshield an A-pillar. There was a lot to keep track of in this, so I figured it was worth the investment in time to make this little jig. When I no longer need it, the wood will be donated to the fire gods in my wood stove....

Here is another quick shot from the side....

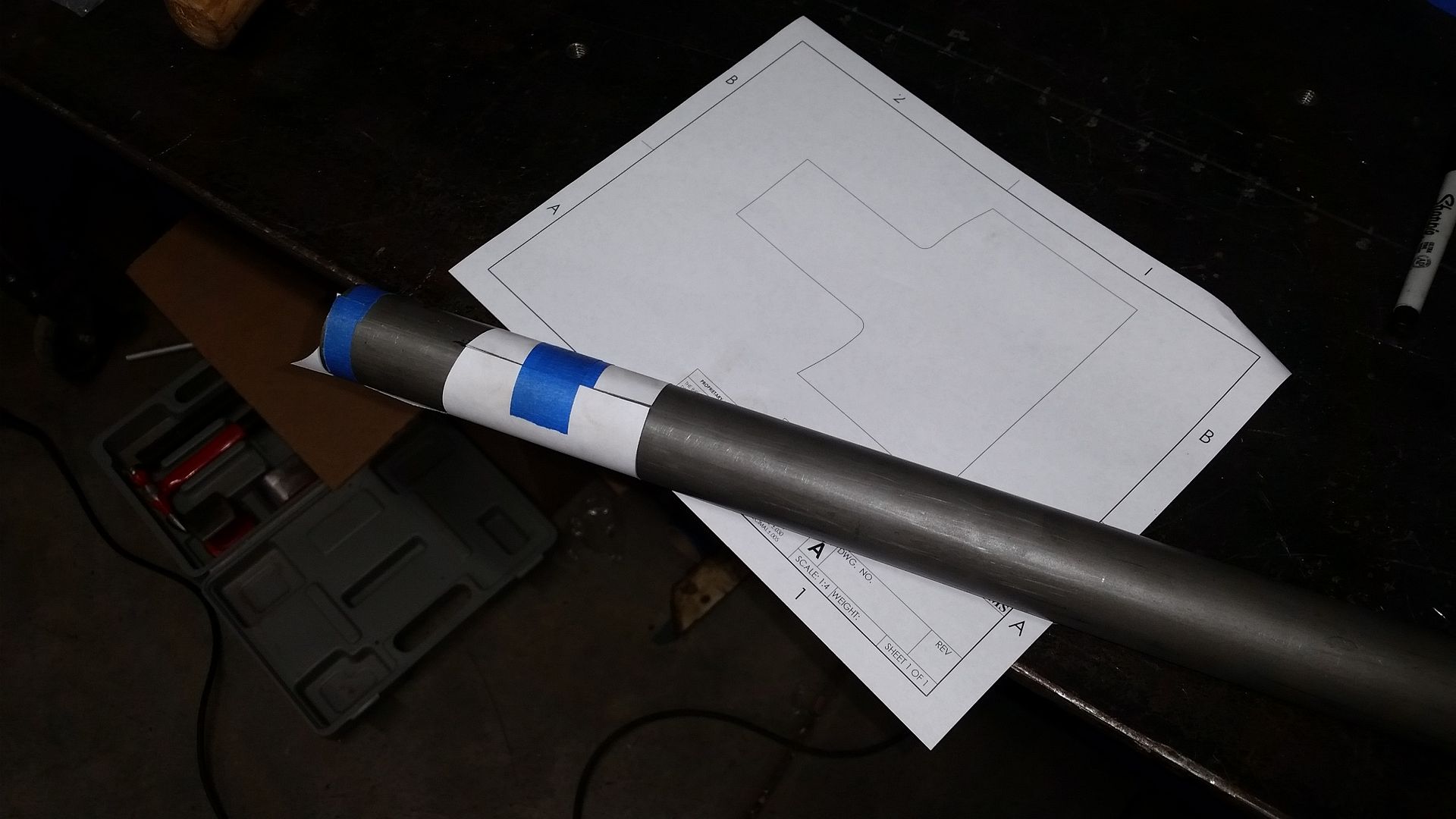

Well, lets play with some tubing! I picked up a HF tubing roller a few weeks back on sale with a coupon. It actually worked way better than I thought it would for the money. It does take a decent amount of force on the feed screw, I ended up using a 1/2" breaker bar and going about 1/8-1/4 of a turn per pass. A single wrap of masking take made a good reference point on where to stop and start. I needed to start and stop in the same spot and have a known length of rolled tubing. I believe that the end of the roll has to go to the centerline of the middle roller. The tail of the roll remains straight from that point out I believe.

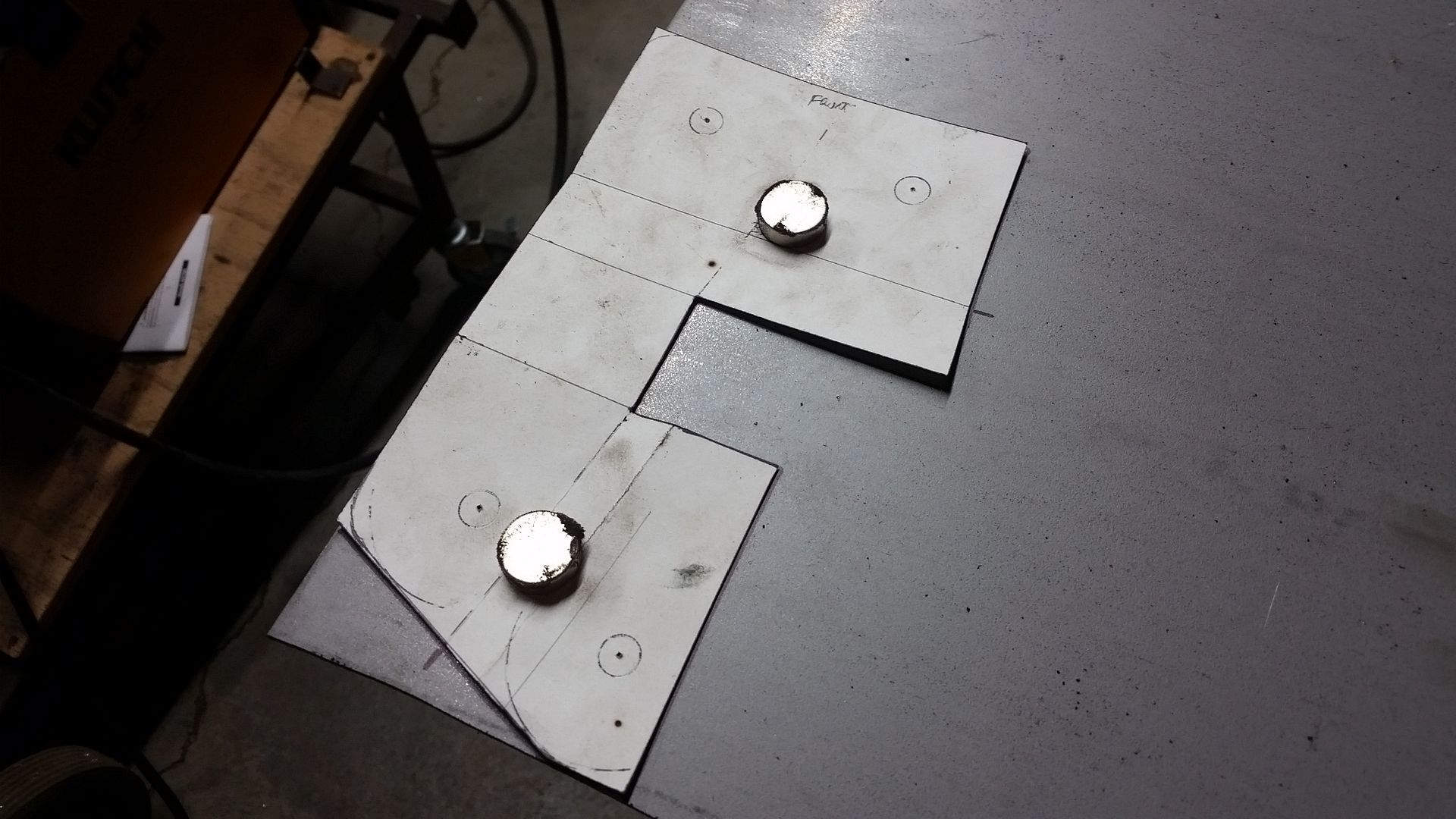

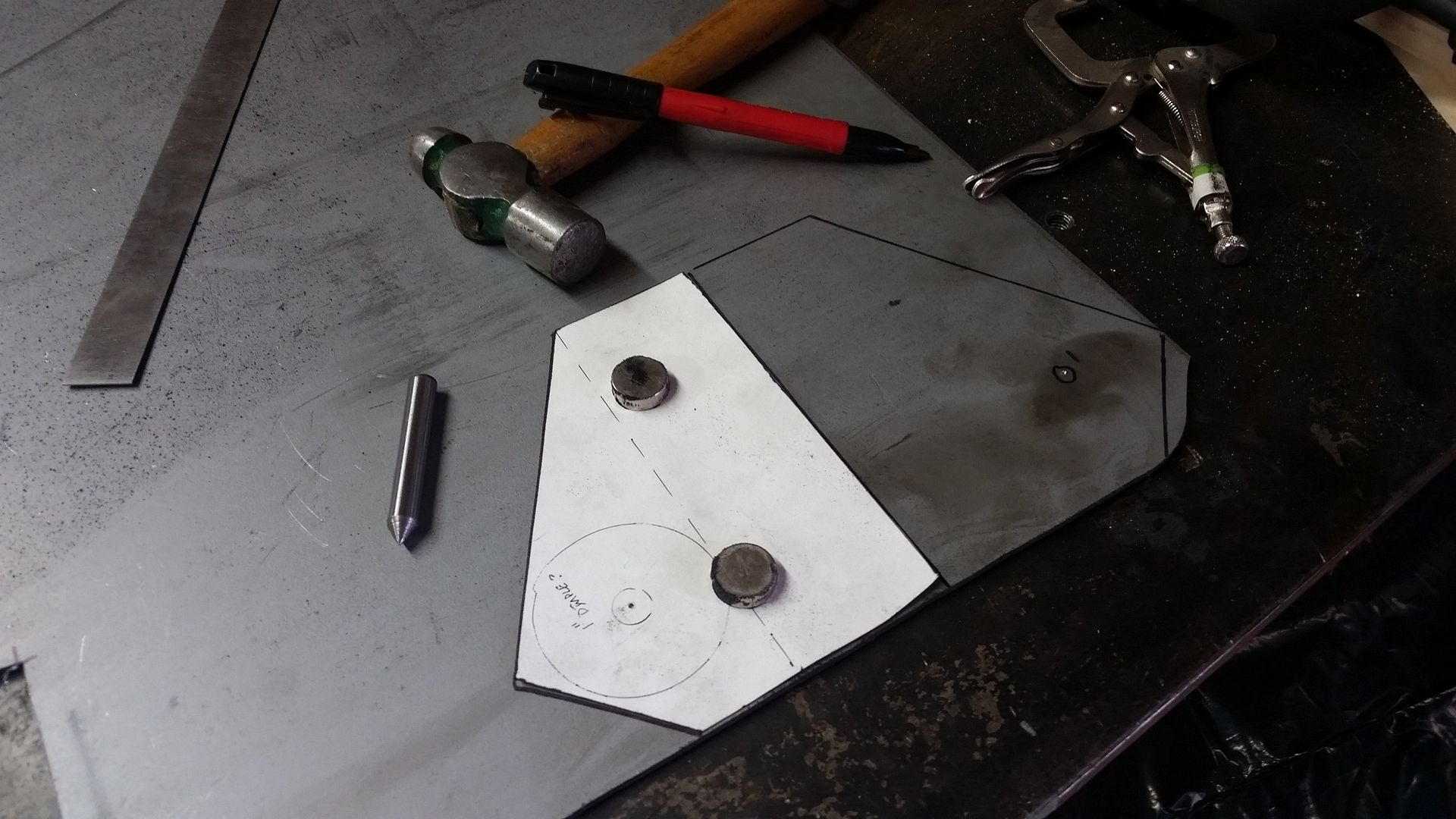

I rigged up a quick jig so I could check the bend radius. For this bend that was .382" of deflection over a 30" span. My welding table just happen to have a 6" grid pattern, so 5 holes is 30" ( or close enough!). The table is tapped for 3/8" threads too. By inserting a two sections of all thread in the table and using a straight piece of tube, I was able to make a crude radius gauge. It was fairly easy to pull the tube out and test the radius in this device so that I could sneak up on the shallow rolled radius I needed to match the windshield.

Since I needed to add 45 degree bends onto each end of tube, I needed to have a 'plane of bend' reference to set it up in the tube bender. I did this by welding on a small 'flag' of bar stock that was parallel to the bend plane. Since the tubing is 1.5" diameter I was able to align this 'flag' by setting it on a section of waste rectangular/square tube that was also 1.5" high. I used two good tack welds and made sure to check the alignment after welding since it will pull a little bit. It was easy to check the alignment with the little scrap section of tubing.

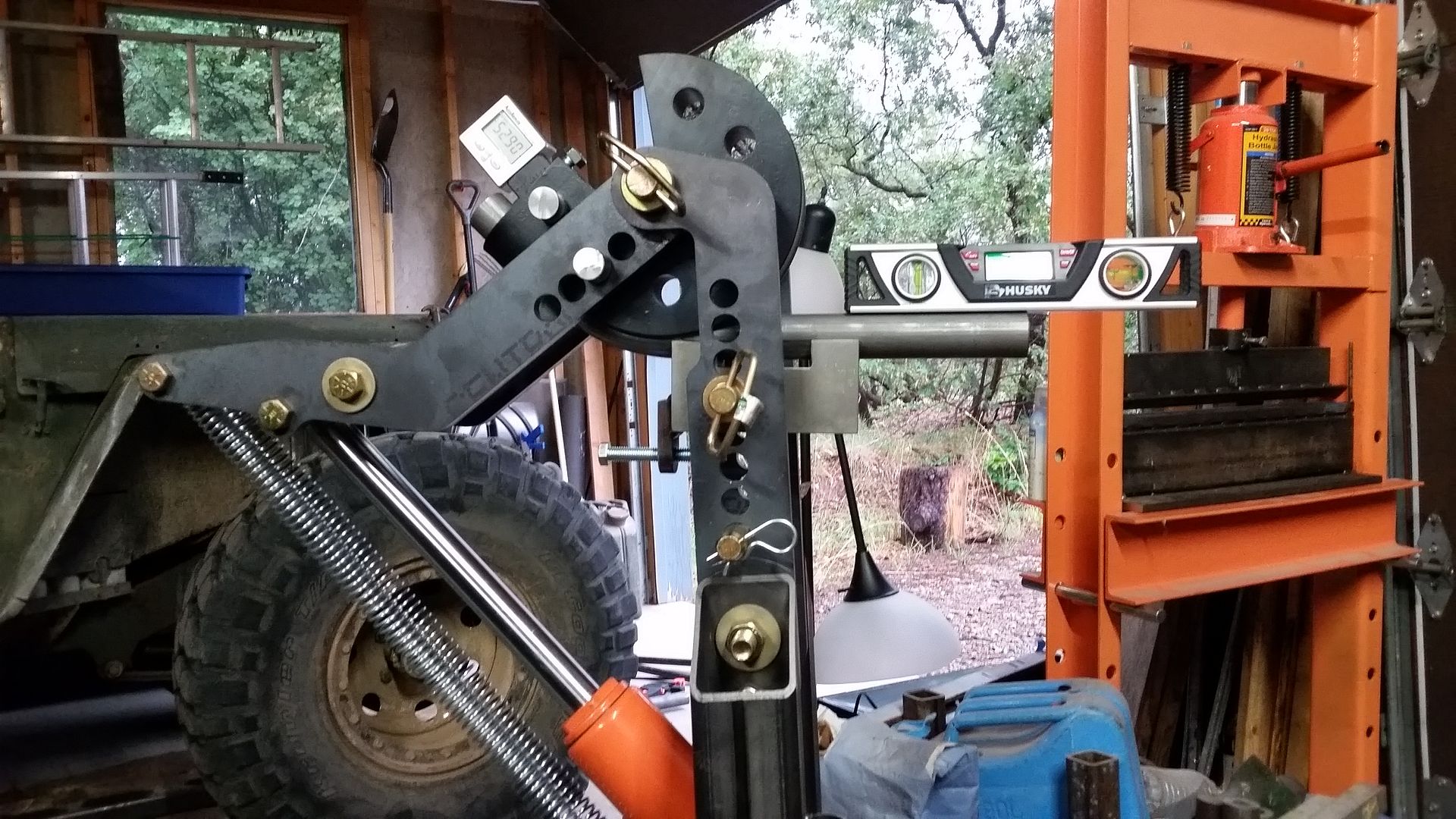

This is how that works when you stick the tubing in the bender. This lets you keep all the bends in alignment. It ended up working out really well overall. I was able to keep all 3 bends....1 rolled large radius, and two 45 bends all in plane while having to move between all 3 different setups.

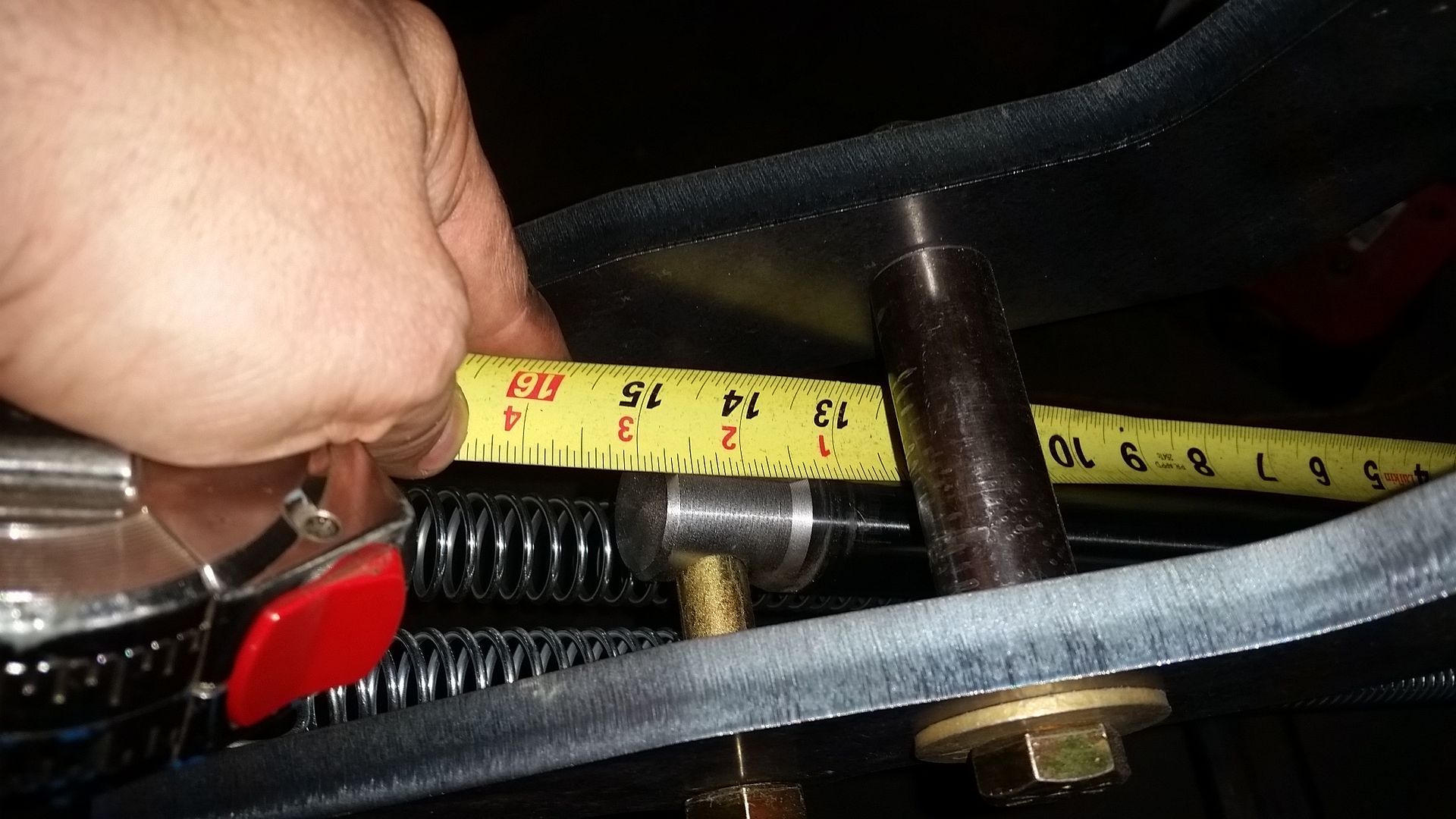

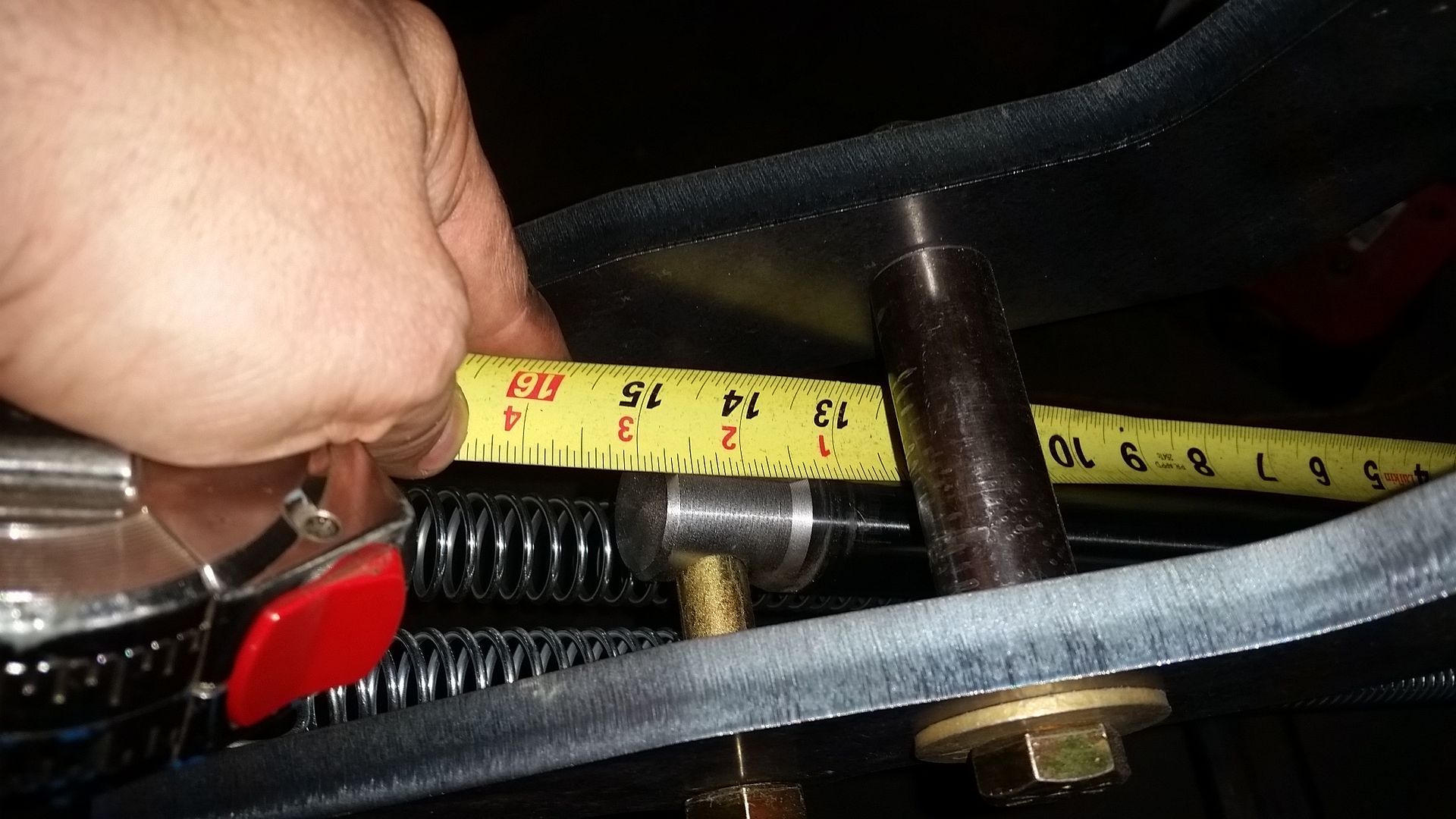

Last tip. On my vertical style bender, I found it very easy to measure the overall ram extension as a bend angle reference. I did a test bend and was able to use that number on the two final bends. It worked sweet, was very accurate, and gave very repeatable bends. Not that it helps me much, but now I know that a 45 degree bend is 14 13/16" of ram extension on this die with 1.5x0.120 wall DOM tubing including springback. I didn't have a lot of level surfaces on the rolled tube or extra tail on the end to use an angle finder. I used the absolute minimum amount of wasted tail on the bends to keep down tube waste. On my machine that is 6" of straight tube in the following die minimum once you figure in spring back. The end of the tube actually sucks up onto the flat of the following die.

I think that is all for now. I still have a lot of work that needs to be done on the cage but all the big parts are made. The top of the A-pillar tubes need a slight trim to match the windshield spreader. I need to make and fit the gussets. Then I will finally be able to take it apart and weld everything...I think....unless I forgot something.......