A big bite tonight....

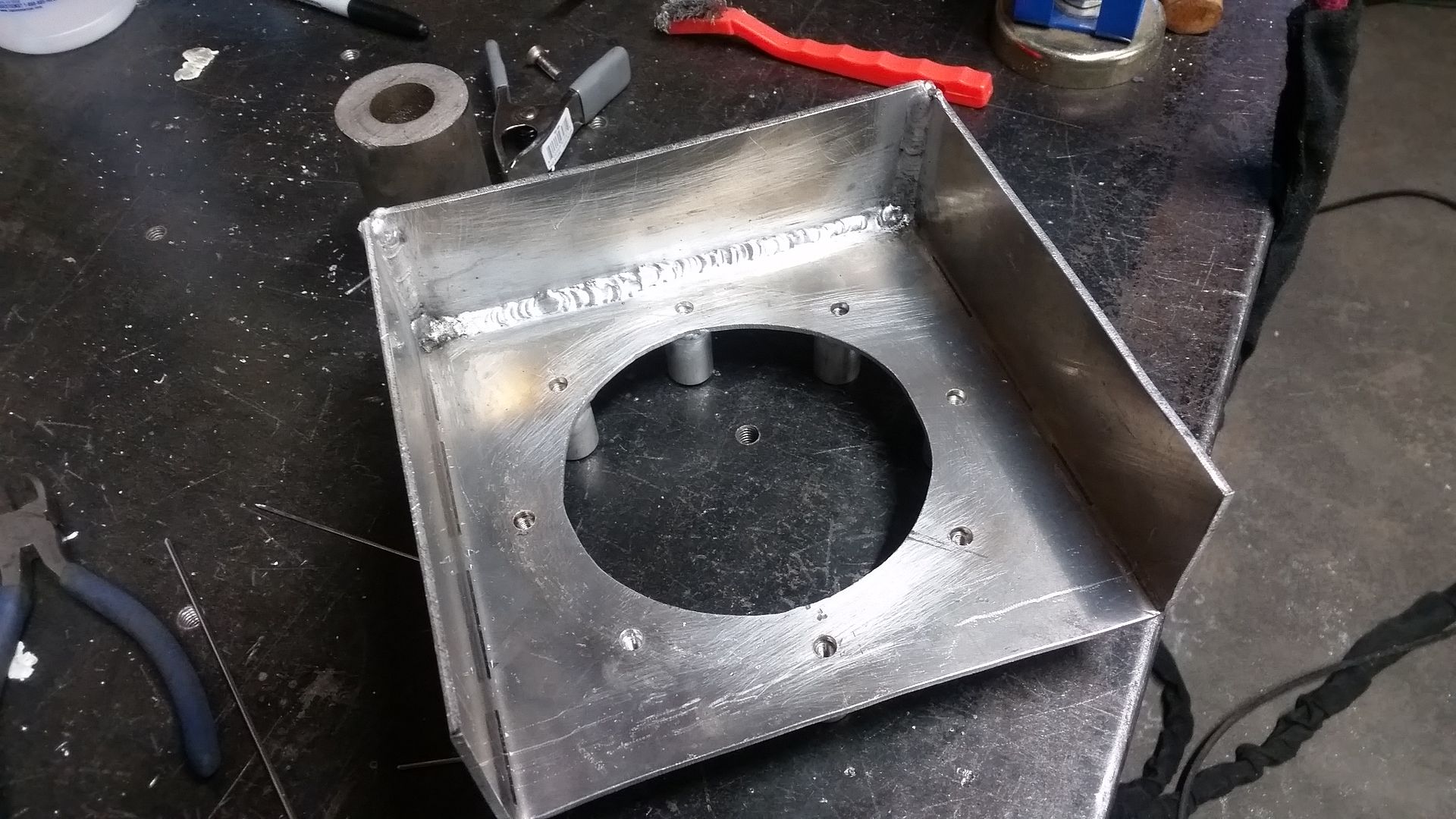

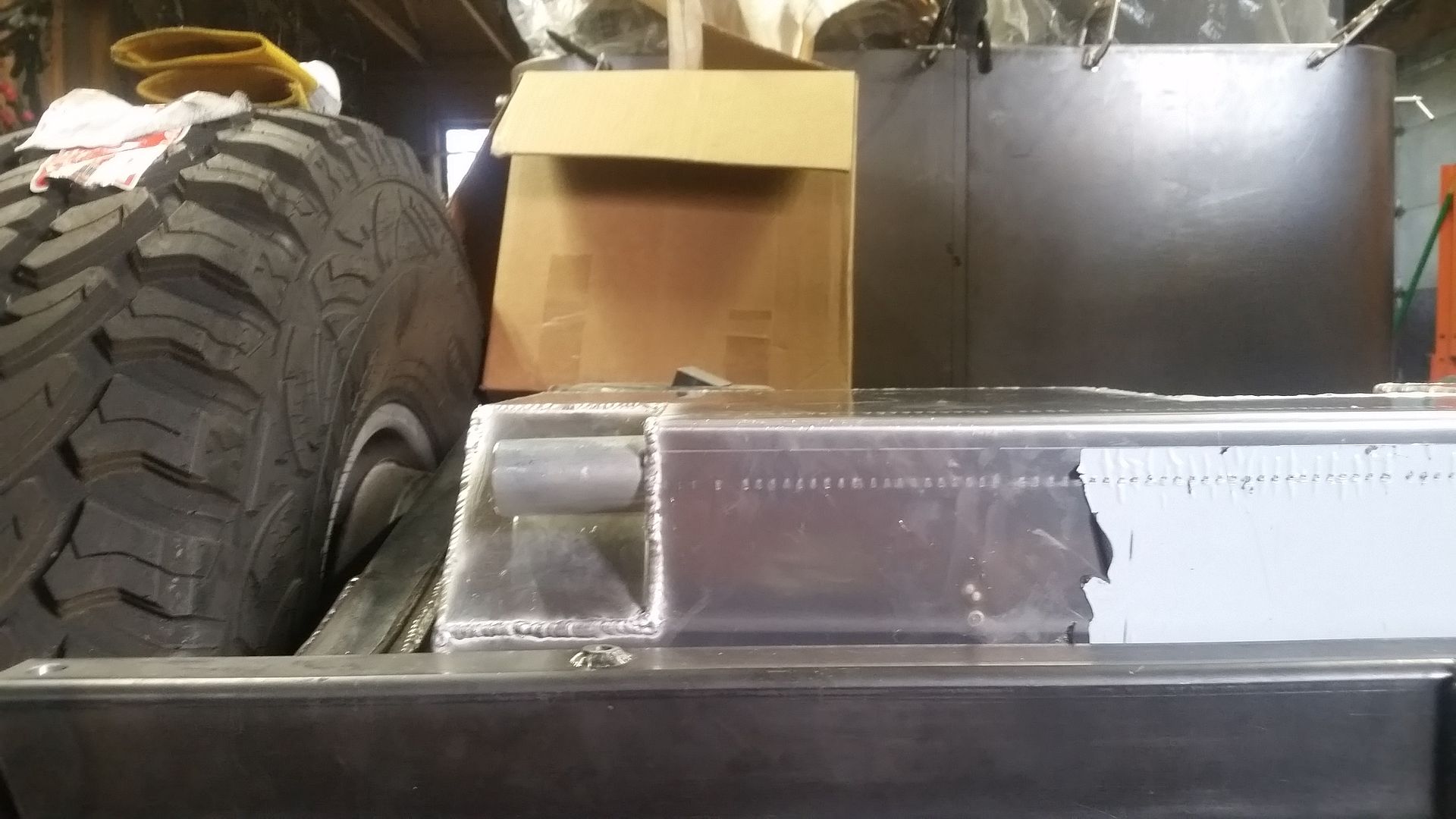

I got the 2nd end cap cut, fitted, and tack welded in place. This side has a little extra cut out where the fuel filler tube will go....

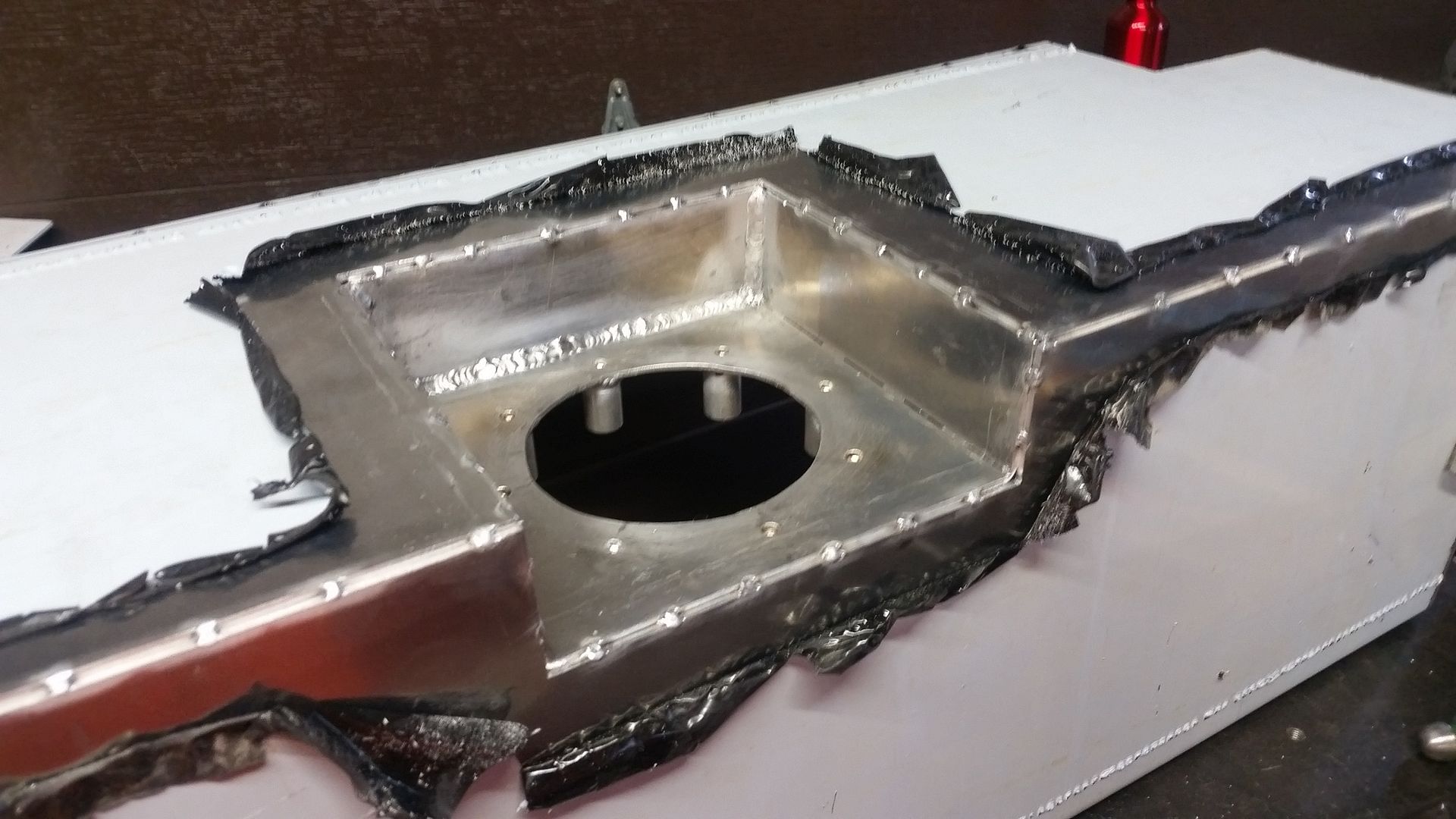

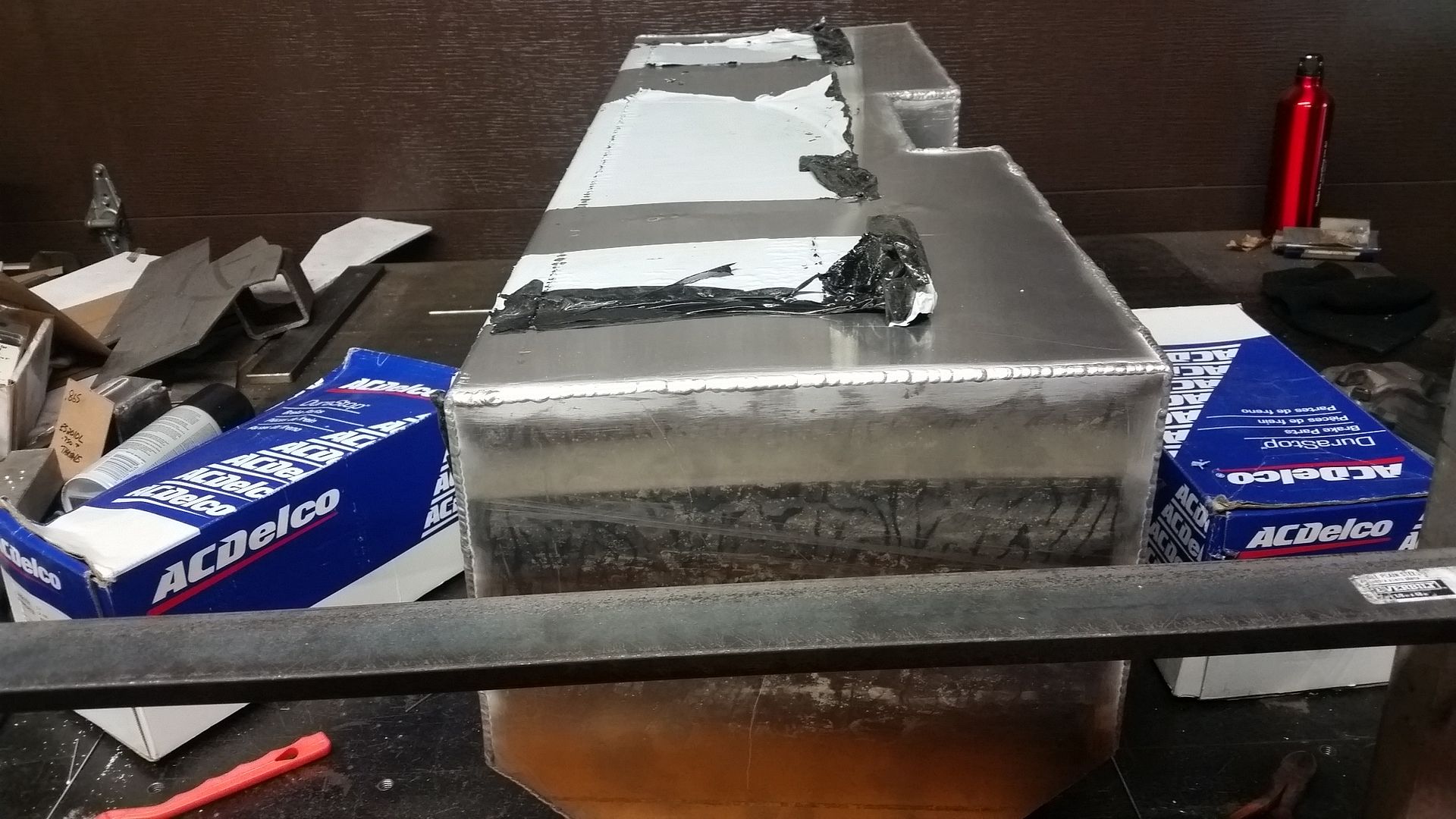

I cobbled up a hand rest for doing all the long welds. This was easy to adjust for height also which came in handy for all the different positions. A few heavy boxes worked great for keeping the tank on edge while I welded the odd seam on the rear bottom of the tank taper.

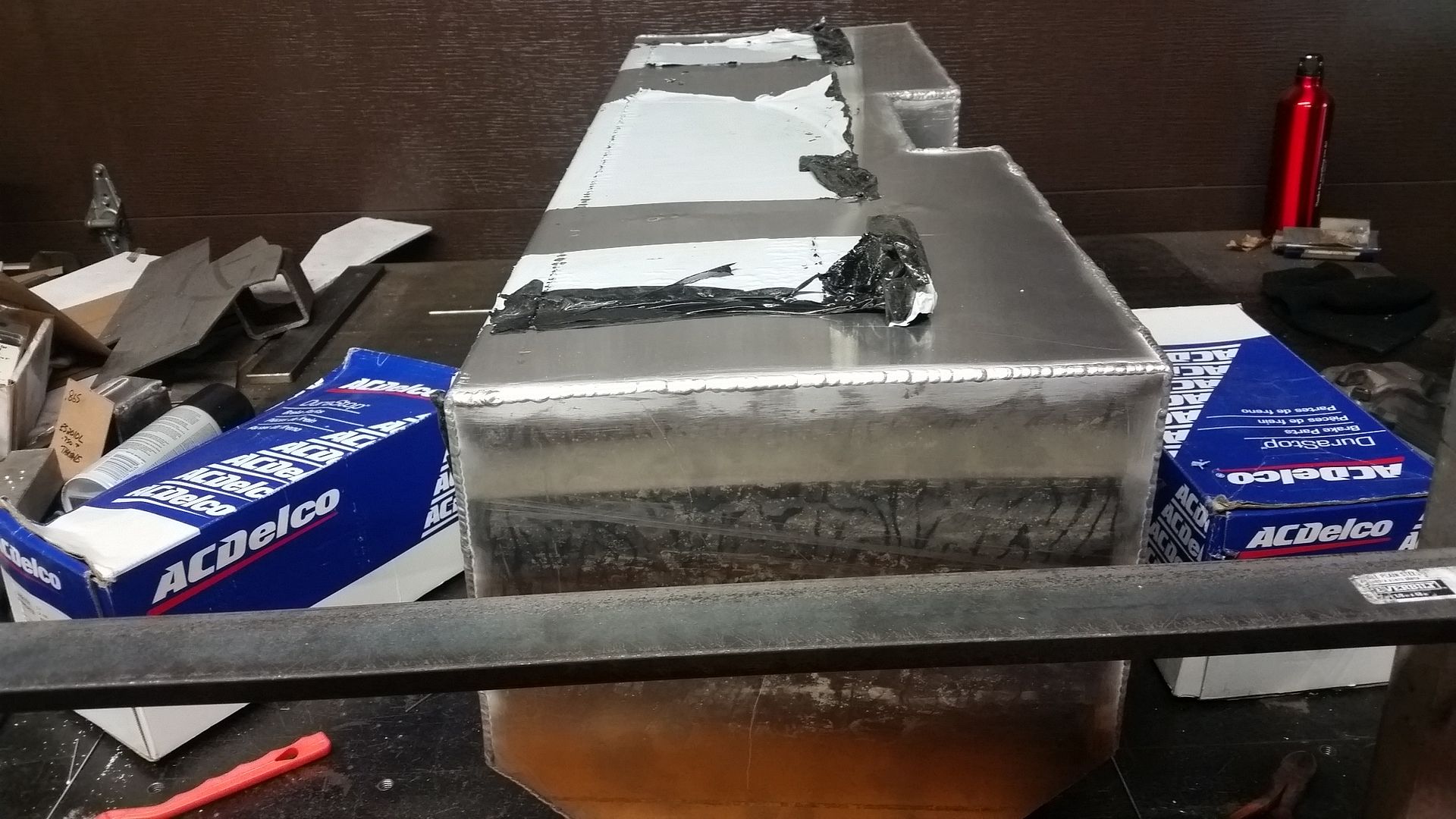

Something finally clicked with the TIG welding of aluminum finally. This setup was AC, 100% argon, 15cfh, 100 amps, 17 air cooled torch, sharp 3/32nd 2% lanthinated Tungsten, #5 cup, about 3/16 stick out. I was running the pedal about 80-90% depending on how warm the entire part was getting. I am using 1/16th 5356 filler on the 1/8" 5052-H32 material.

I think the biggest improvement came from changing over to my #10 passive welding helmet. This was like taking the blinders off pretty much. It allowed me to see every detail in the puddle. It felt like I had about 3x more time to see a problem/change in the puddle before bad things started happening. The arm rest made things a lot more stable for both hands also.

Good ol' passive helmet. While the auto dark is fine for tack welding, for long welds I keep coming back to the passive.

Both ends all welded up. The only welding left is the filler neck part! It felt huge to get the ends welded on.

Shop tip. If you are going to use some masking tape to hold the aluminum panel in place, make a little tab on one end so you can remove the tape with your welding gloves on. This keeps you from having to remove a glove to remove the tape as you tack weld the panel in place.