Metcalf

Expedition Leader

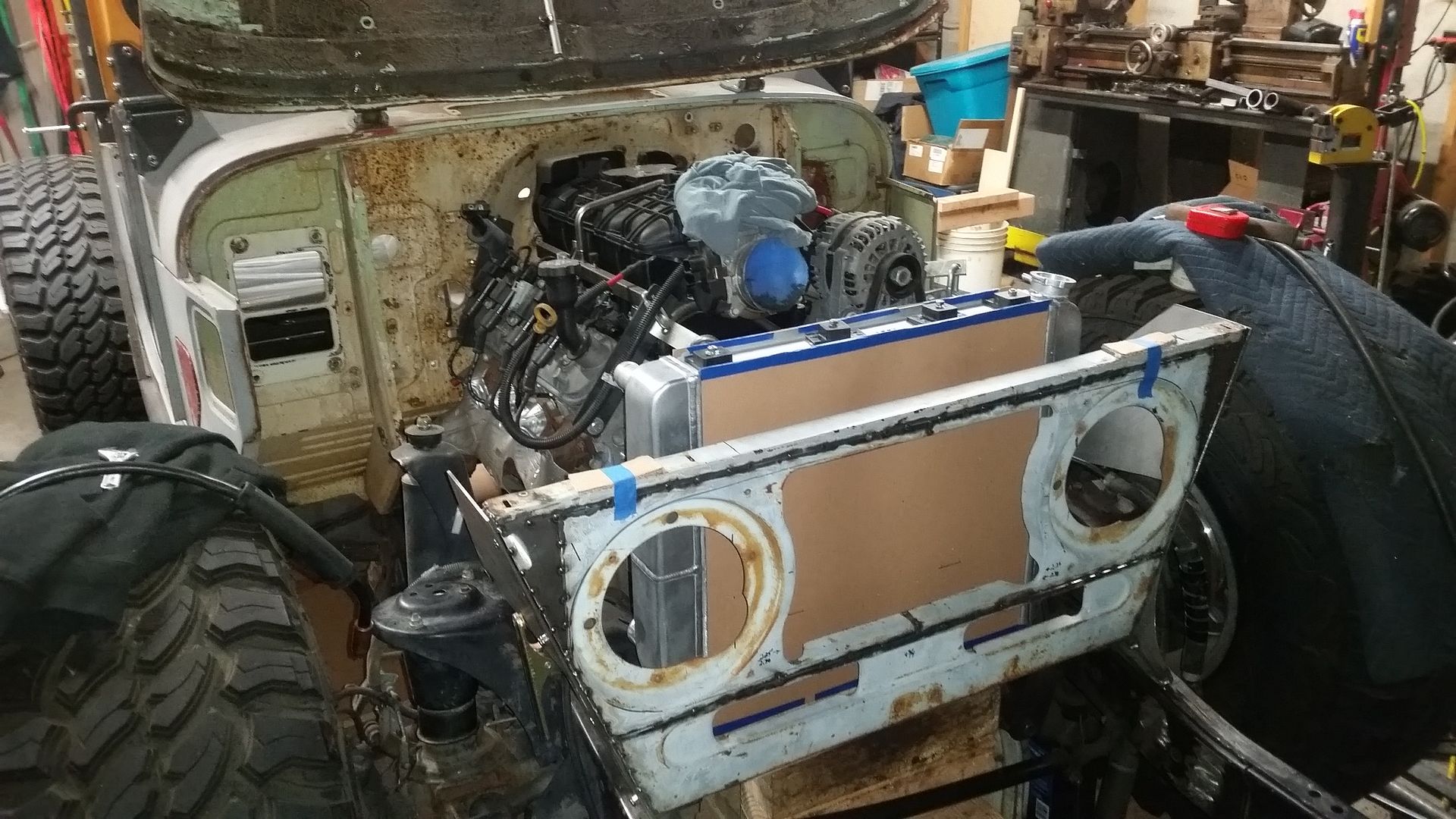

Bigger parts are showing up!

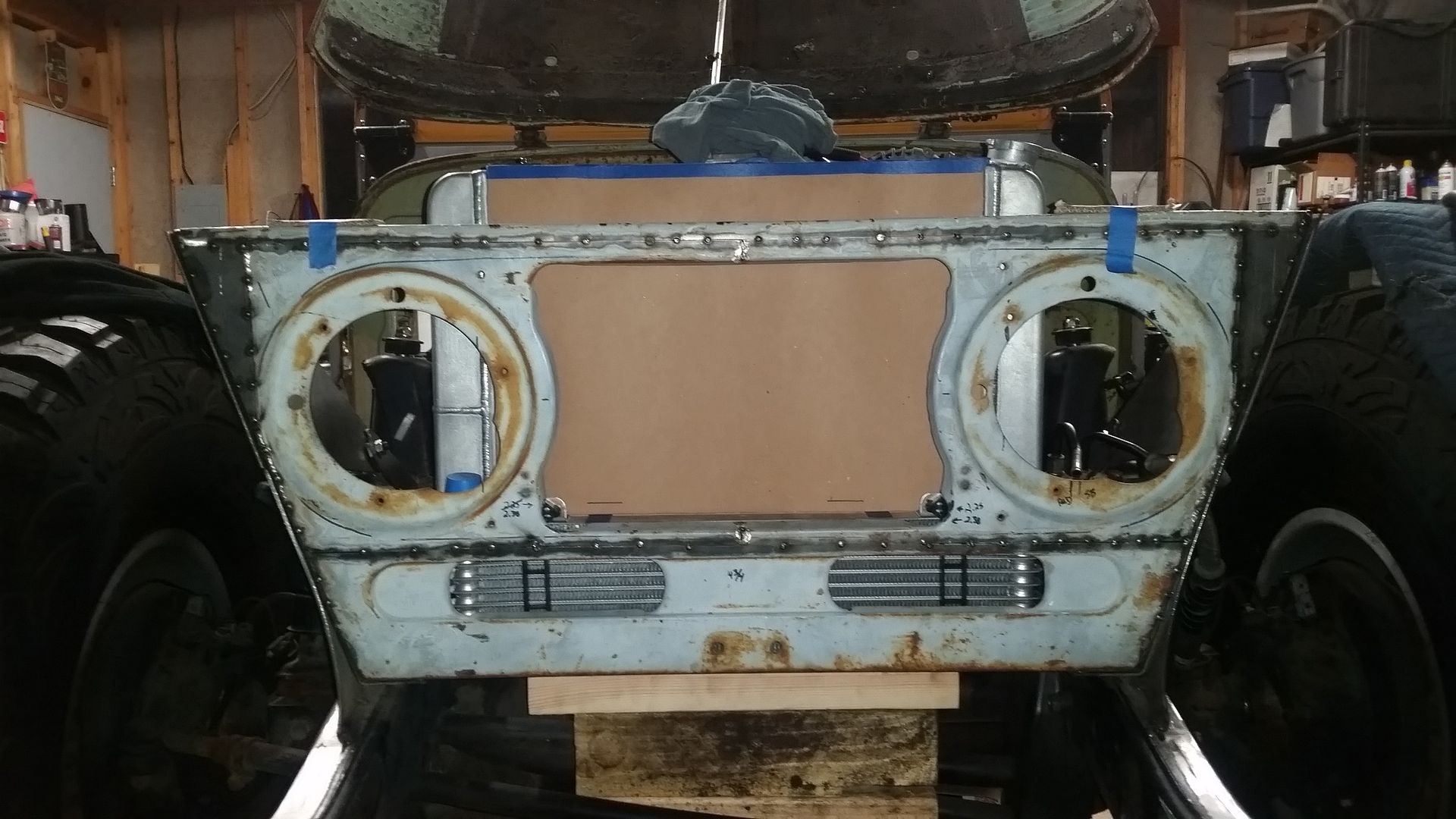

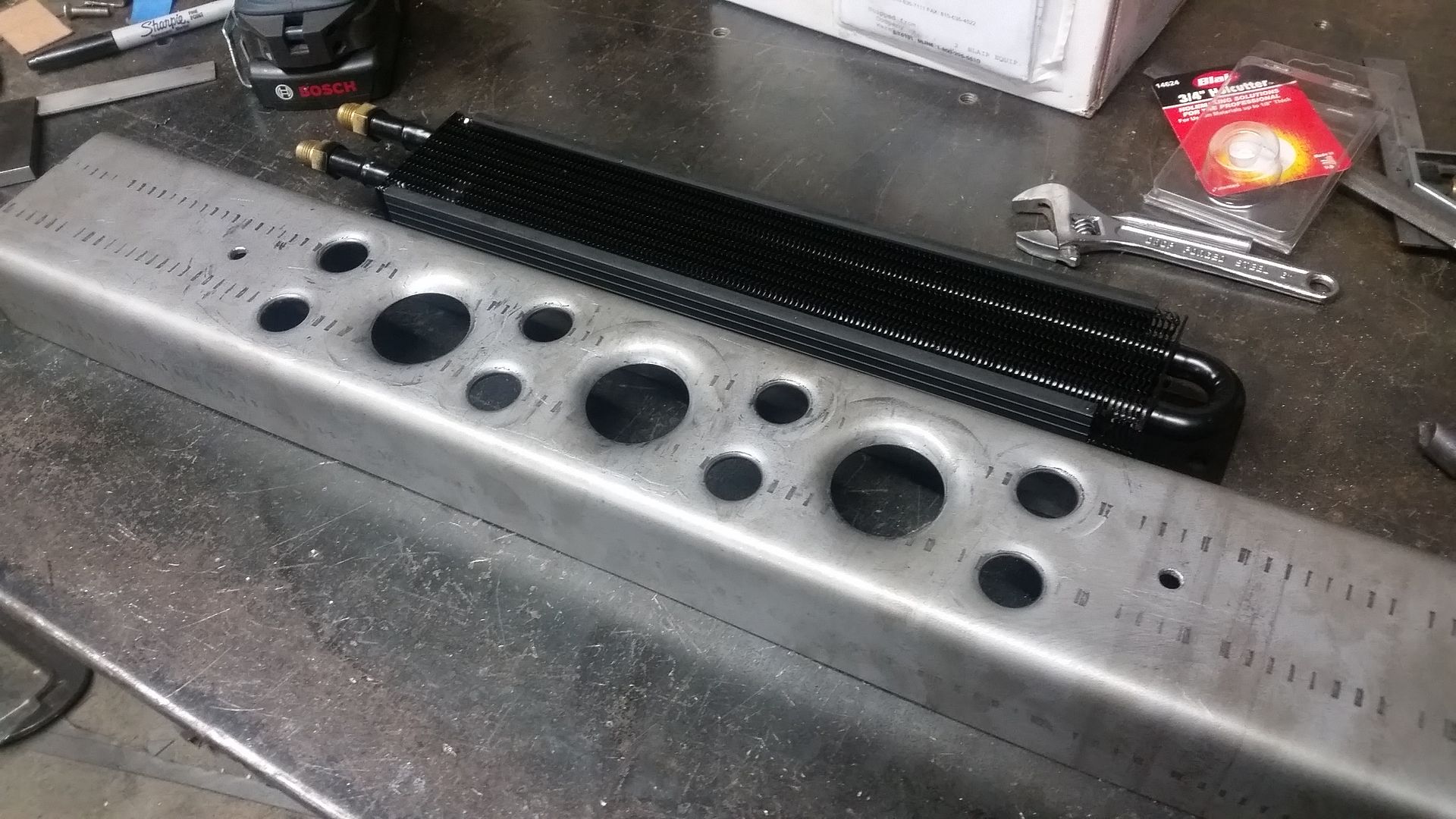

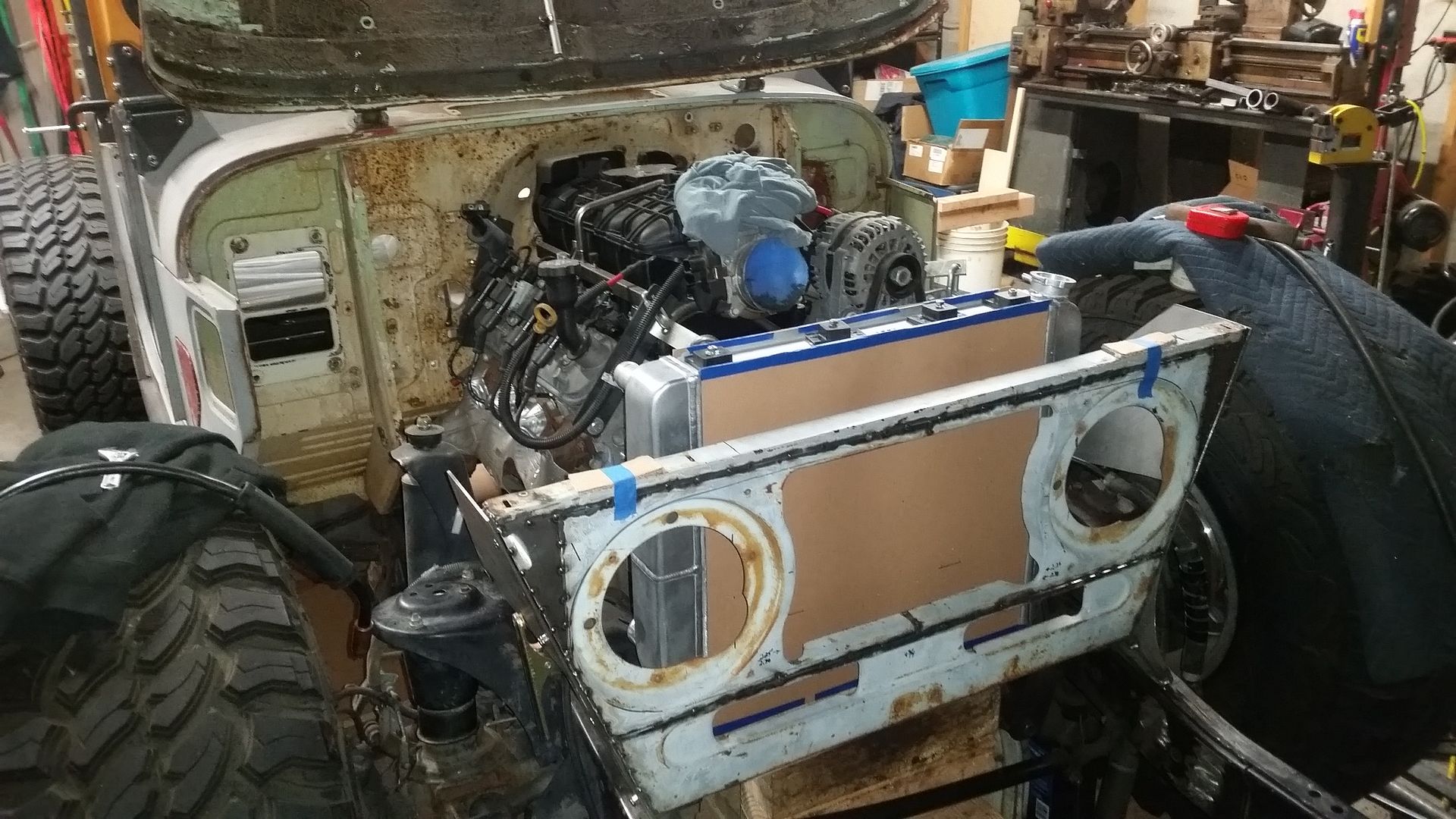

I was able to finish the mockup on the upper grill mounts and get them tacked into place. Once that was done I decided to mock up the radiator into position since it showed up today.

Radiator specs.

Brand:Griffin Thermal Products

Manufacturer's Part Number:1-58202-XLS

Griffin Aluminum Circle Track Radiators

Radiator Style: Crossflow

Inlet Location: Upper passenger side

Outlet Location: Lower passenger side

Radiator Material: Aluminum

Radiator Finish: Natural

Overall Width (in): 24.000 in.

Overall Height (in): 19.000 in.

Overall Thickness (in): 3.000 in.

Core Width (in): 19.000 in.

Core Height (in): 19.000 in.

Core Thickness (in): 2.680 in.

Row Quantity: 2

Transmission Cooler: No

Inlet Size: 1 1/4 in.

Outlet Size: 1 1/2 in.

Tube Size: 1 1/4 in.

This is about the largest radiator I can fit in this chassis. The steering box is mounted on top of the frame rail on this chassis just behind the grille. The radiator is offset slightly to provide clearance on the steering box. I ended up trying to center the radiator top to bottom on the fan clutch centerline. That should make building the radiator shroud a bit easier.

I edited the above post. I have the wrong fan clutch. New one on the way. I must have got my numbers crossed somewhere. I think the proper clutch I had planned will give me even more clearance....and match up to the fan that showed up today too.

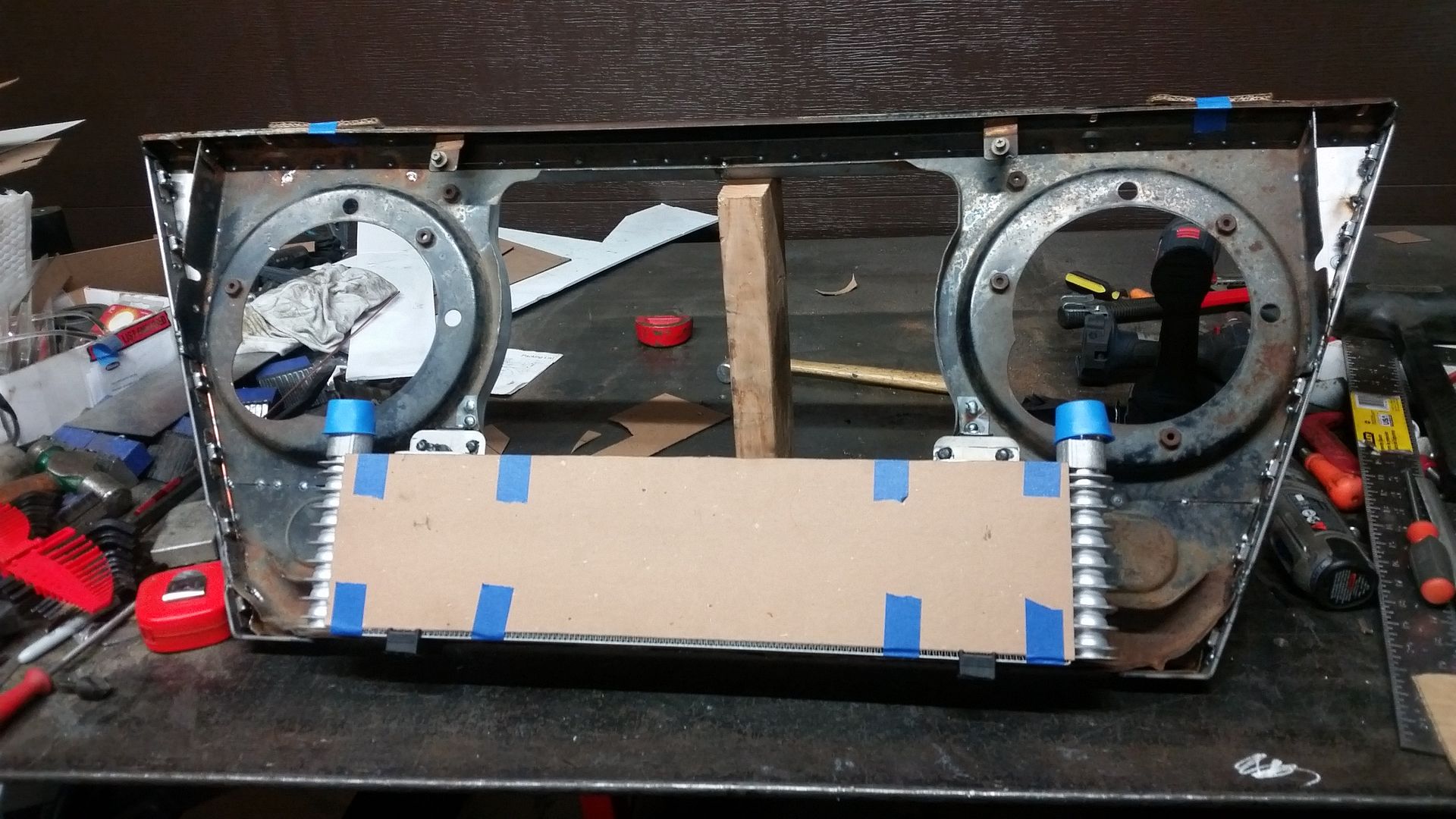

I stumbled on these little rubber radiator mounts from a Jeep XJ. The are a nice stud mount rubber isolation mounting system. They where SO close to fitting in the stock core u-channel. I ended up having to trim about 1/8" off one side of the mount. They have a 6mm stud on the top. They also clear the height of the u-channel by just enough. My hope is that I can use these to isolate the radiator from the frame mounting of the grill a bit. I am going to wait to do another mockup till I have the proper fan clutch. I think it is a bit shorter in length....

I was able to finish the mockup on the upper grill mounts and get them tacked into place. Once that was done I decided to mock up the radiator into position since it showed up today.

Radiator specs.

Brand:Griffin Thermal Products

Manufacturer's Part Number:1-58202-XLS

Griffin Aluminum Circle Track Radiators

Radiator Style: Crossflow

Inlet Location: Upper passenger side

Outlet Location: Lower passenger side

Radiator Material: Aluminum

Radiator Finish: Natural

Overall Width (in): 24.000 in.

Overall Height (in): 19.000 in.

Overall Thickness (in): 3.000 in.

Core Width (in): 19.000 in.

Core Height (in): 19.000 in.

Core Thickness (in): 2.680 in.

Row Quantity: 2

Transmission Cooler: No

Inlet Size: 1 1/4 in.

Outlet Size: 1 1/2 in.

Tube Size: 1 1/4 in.

This is about the largest radiator I can fit in this chassis. The steering box is mounted on top of the frame rail on this chassis just behind the grille. The radiator is offset slightly to provide clearance on the steering box. I ended up trying to center the radiator top to bottom on the fan clutch centerline. That should make building the radiator shroud a bit easier.

I edited the above post. I have the wrong fan clutch. New one on the way. I must have got my numbers crossed somewhere. I think the proper clutch I had planned will give me even more clearance....and match up to the fan that showed up today too.

I stumbled on these little rubber radiator mounts from a Jeep XJ. The are a nice stud mount rubber isolation mounting system. They where SO close to fitting in the stock core u-channel. I ended up having to trim about 1/8" off one side of the mount. They have a 6mm stud on the top. They also clear the height of the u-channel by just enough. My hope is that I can use these to isolate the radiator from the frame mounting of the grill a bit. I am going to wait to do another mockup till I have the proper fan clutch. I think it is a bit shorter in length....