Curtis in Texas

Adventurer

I wish I had those computer skills. Would love to be able to show people what I see in my head.

I can visualize something then go into the shop, make a few notes about dimensions and build it.

But, trying to explain it in drawings is tough when people can't read napkin!

*

*

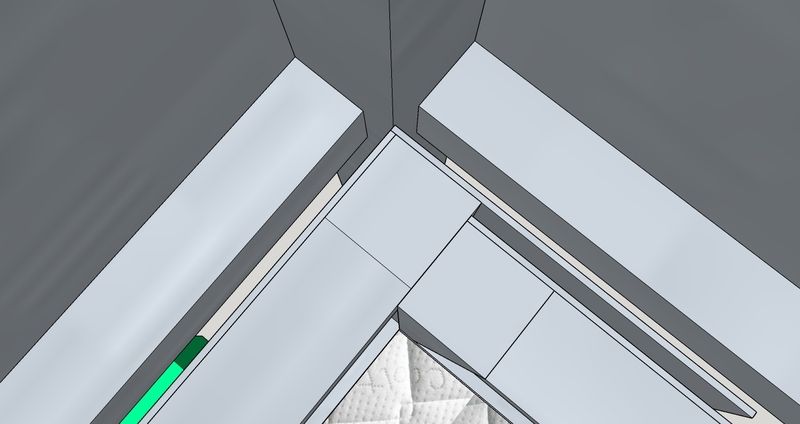

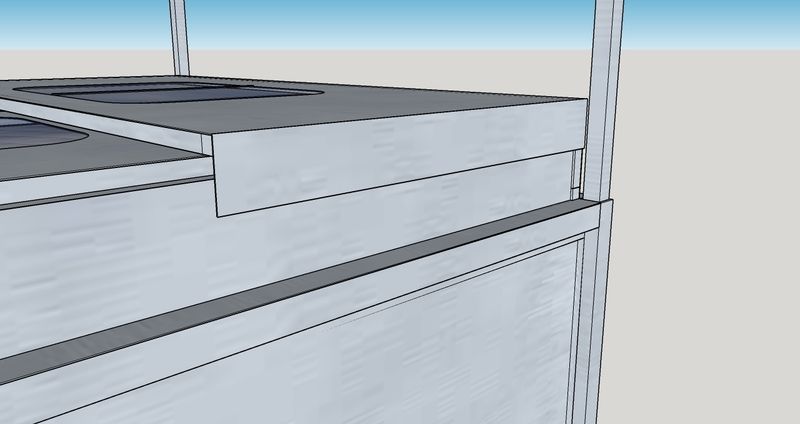

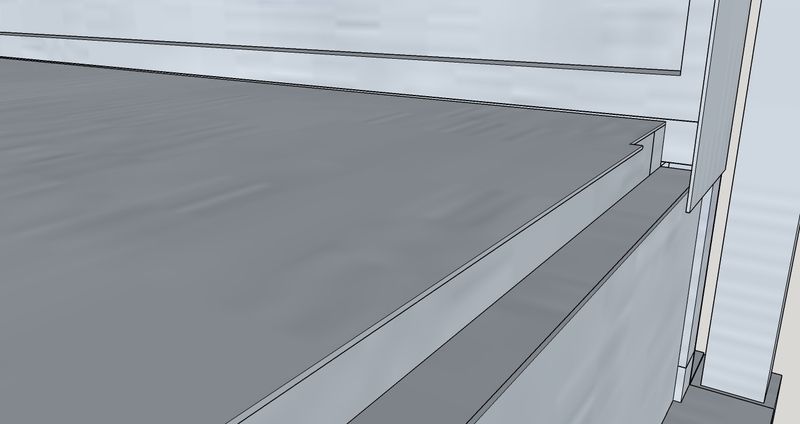

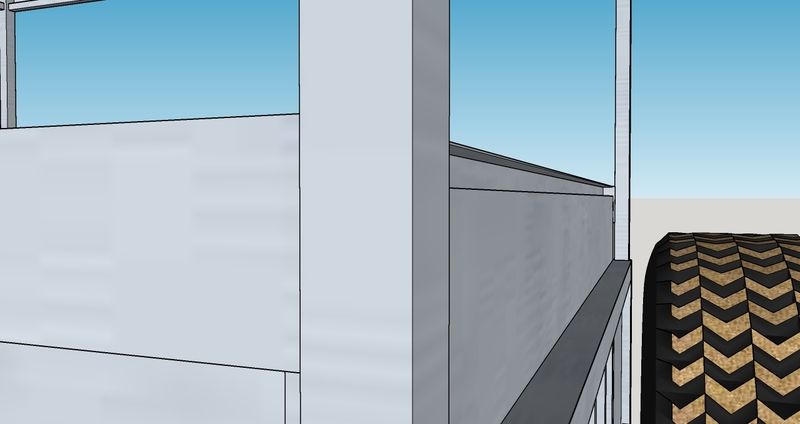

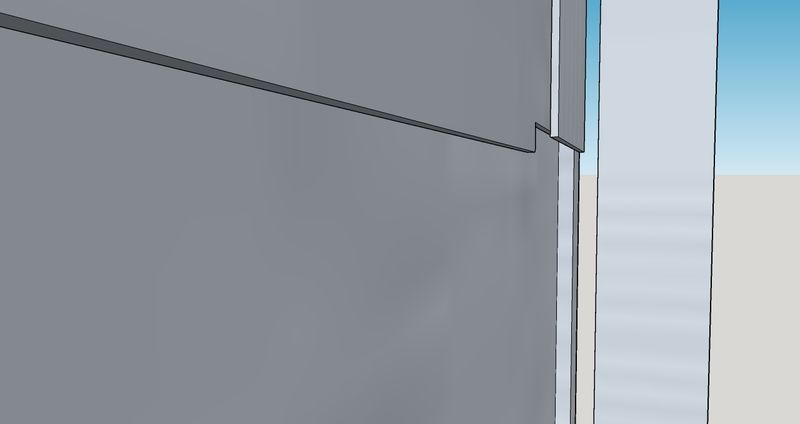

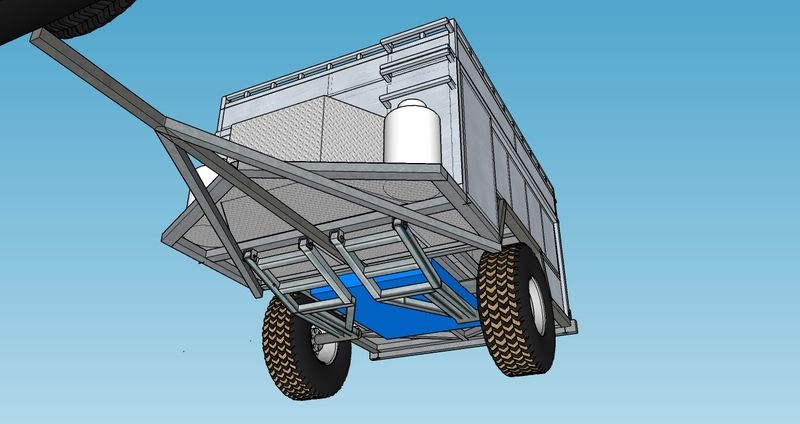

I found a rendering someone posted up on this Forum several years ago that closely represents what I'm planning on my build looking like.

( I don't know who's work it is so if someone recognizes it shout out. I would love to give him credit for the computer drawing. Mainly so he can follow my build and see his idea come together.)

*

*

*

The main difference other than more length and width is it's suspension.

Mt frame has Independent torsion bar "A" arms suspension with electric remote control steering.

I camp in a lot of tight places where just getting there between the tree lined trails is a challenge.

*

*

*

Thinking about adding air shocks to the torsion bar adjusters so I can control ride height in motion.

May add it later if it needs it, since I've already figured out how to make it work.

*

*

*

My frame is done and the remote steering works.

*

*

*

I'm now fitting the floor to the frame. Once I get the body formed out I'll start a thread to catch everyone up with the progress. I'm a slow builder. Mainly life gets in the way. (Children, Grandchildren, friends and other hobbies) (Motorcycles and 4X4 Junky!)

*

*

*

I worked 3 years for Williamscraft Camper and Mobile Home Manufacturing back in the early 70's.

Going to build mine with the skill set they taught me way back when, with some new construction methods that have been developed since then.

*

Going to enjoy watching your build. Aluminum is always a cool material to work with.

*

*

Mine will look somewhat like this one, only more length, width and slightly taller.

NO front storage, because all the tanks are built between the frame fails.

I can visualize something then go into the shop, make a few notes about dimensions and build it.

But, trying to explain it in drawings is tough when people can't read napkin!

*

*

I found a rendering someone posted up on this Forum several years ago that closely represents what I'm planning on my build looking like.

( I don't know who's work it is so if someone recognizes it shout out. I would love to give him credit for the computer drawing. Mainly so he can follow my build and see his idea come together.)

*

*

*

The main difference other than more length and width is it's suspension.

Mt frame has Independent torsion bar "A" arms suspension with electric remote control steering.

I camp in a lot of tight places where just getting there between the tree lined trails is a challenge.

*

*

*

Thinking about adding air shocks to the torsion bar adjusters so I can control ride height in motion.

May add it later if it needs it, since I've already figured out how to make it work.

*

*

*

My frame is done and the remote steering works.

*

*

*

I'm now fitting the floor to the frame. Once I get the body formed out I'll start a thread to catch everyone up with the progress. I'm a slow builder. Mainly life gets in the way. (Children, Grandchildren, friends and other hobbies) (Motorcycles and 4X4 Junky!)

*

*

*

I worked 3 years for Williamscraft Camper and Mobile Home Manufacturing back in the early 70's.

Going to build mine with the skill set they taught me way back when, with some new construction methods that have been developed since then.

*

Going to enjoy watching your build. Aluminum is always a cool material to work with.

*

*

Mine will look somewhat like this one, only more length, width and slightly taller.

NO front storage, because all the tanks are built between the frame fails.