Looking for some advice on an idea I'm trying to make a reality.

I'm trying to create more surface area at the rear of an FJ80 than exist with the OE Tailgate. My idea is to attach folding pieces of wood to my already existing simplistic storage platform.

I have already cut/mounted the first piece which covers 80% of the tailgate width. I'm now looking for advice on how to attach and support the second piece which will have approx. 3 in. overlap on the tailgate and remainder off. Arrow shows the piece I'm talking about.

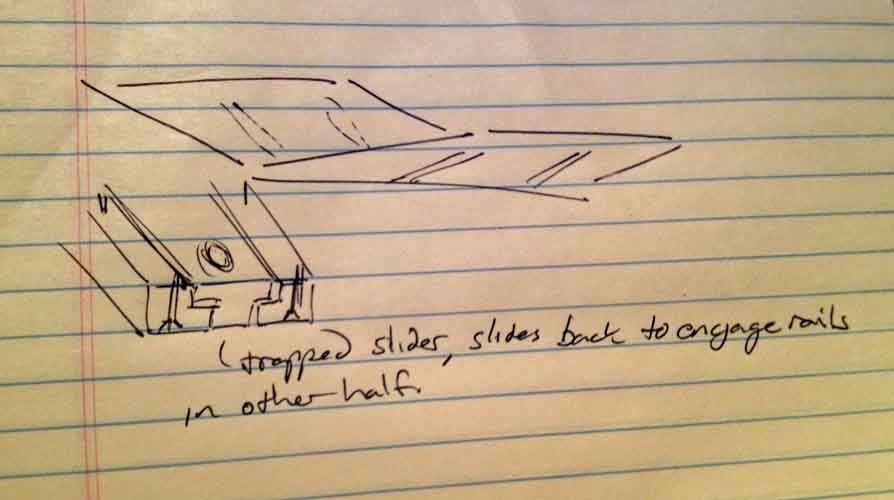

My initial idea was to use a piano hinge but I'm beginning to sway away from that as it will disrupt the seamlessness of the surface as seen in the image below.

Extended out:

Folded up:

Thanks!

I'm trying to create more surface area at the rear of an FJ80 than exist with the OE Tailgate. My idea is to attach folding pieces of wood to my already existing simplistic storage platform.

I have already cut/mounted the first piece which covers 80% of the tailgate width. I'm now looking for advice on how to attach and support the second piece which will have approx. 3 in. overlap on the tailgate and remainder off. Arrow shows the piece I'm talking about.

My initial idea was to use a piano hinge but I'm beginning to sway away from that as it will disrupt the seamlessness of the surface as seen in the image below.

Extended out:

Folded up:

Thanks!

Attachments

Last edited: