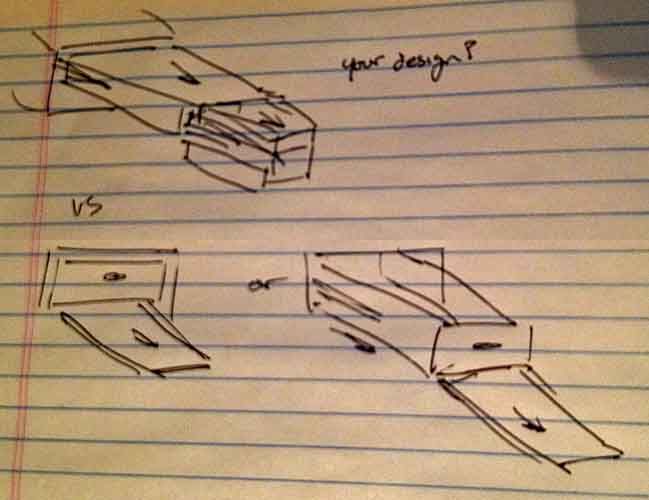

Here's the concept for the inner drawer box inserts that might allow for the modules to be flipped over, upside-down:

The inner drawer would work more like a tray or frame with an open bottom. This frame would have two mounting ledges, located front and rear, which could serve as mounting points for a box insert. These mounting ledges would be located at the midpoint of the drawer frame's vertical dimension. This location would allow a box insert to be mounted on these ledges in either orientation: right-side-up or upside-down.

The box insert would be a simple box, with two matching front and back ledges, that would rest on top of the corresponding ledges inside the above-described drawer frame. I would plan to make several of these boxes in order to easily swap pre-packed sets of gear into the frame, depending on the purpose of any given trip.

Now, because the slides are stacked vertically, the lower slide (which services the drawer frame in question) occupies the space where the mounting ledge would be located; precluding the mounting of any ledges on the sides of the inner drawer frame. For that reason, the mounting ledges are located at the front and back of the drawer frame, where there are no slides.

At the rear of the drawer frame, there's a similar conflict with the back of the drawer frame and slide, so I simply notched the drawer frame's rear panel so that it could slide past the slides:

The inner drawer would work more like a tray or frame with an open bottom. This frame would have two mounting ledges, located front and rear, which could serve as mounting points for a box insert. These mounting ledges would be located at the midpoint of the drawer frame's vertical dimension. This location would allow a box insert to be mounted on these ledges in either orientation: right-side-up or upside-down.

The box insert would be a simple box, with two matching front and back ledges, that would rest on top of the corresponding ledges inside the above-described drawer frame. I would plan to make several of these boxes in order to easily swap pre-packed sets of gear into the frame, depending on the purpose of any given trip.

Now, because the slides are stacked vertically, the lower slide (which services the drawer frame in question) occupies the space where the mounting ledge would be located; precluding the mounting of any ledges on the sides of the inner drawer frame. For that reason, the mounting ledges are located at the front and back of the drawer frame, where there are no slides.

At the rear of the drawer frame, there's a similar conflict with the back of the drawer frame and slide, so I simply notched the drawer frame's rear panel so that it could slide past the slides: