I have been browsing this forum for almost a year now. I come here to look at other peoples projects and see what others have done in other situations.

At first I wanted an M416. I found one in Houston and made the drive down and picked it up and drug it home. After tinkering with it for a few months, I realized it wasn't what I really wanted. There is so much prep work with an average condition M416 that I figured I could scratch build me something for the same costs and time.

If you are local to the DFW area, you might have seen my thread so far on the LSJC website.

This is 2 months work so far.

1st, I cleaned up the garage and bought some supplies. The garage was a mess with crap everywhere.

1st order of duty was to build a flat (most concrete floors are not flat) level surface.

That was all I got done last night.

This morning the real work started. I started by laying out my plan on the plywood platform. I used some 2x4 scraps to build a fixture to hole parts in place and assist with assembly.

On a side note, if you are goin to cut a lot of steel, buy one of these. Its a Milwaukee Dry Cut saw

It cuts in 1/10 the time a fiber wheel does, no sparks, its precise, almost zero burs, and no black dust. Then get a magnetic broom and you just pick up the clips in a nice quick swipe.

Back on subject, I started cutting the steel and making sure everything fit and was aligned. It was.

Here is the lower frame all laid out.

Then I cut the upper frame. Here it is just placed on the lower frame.

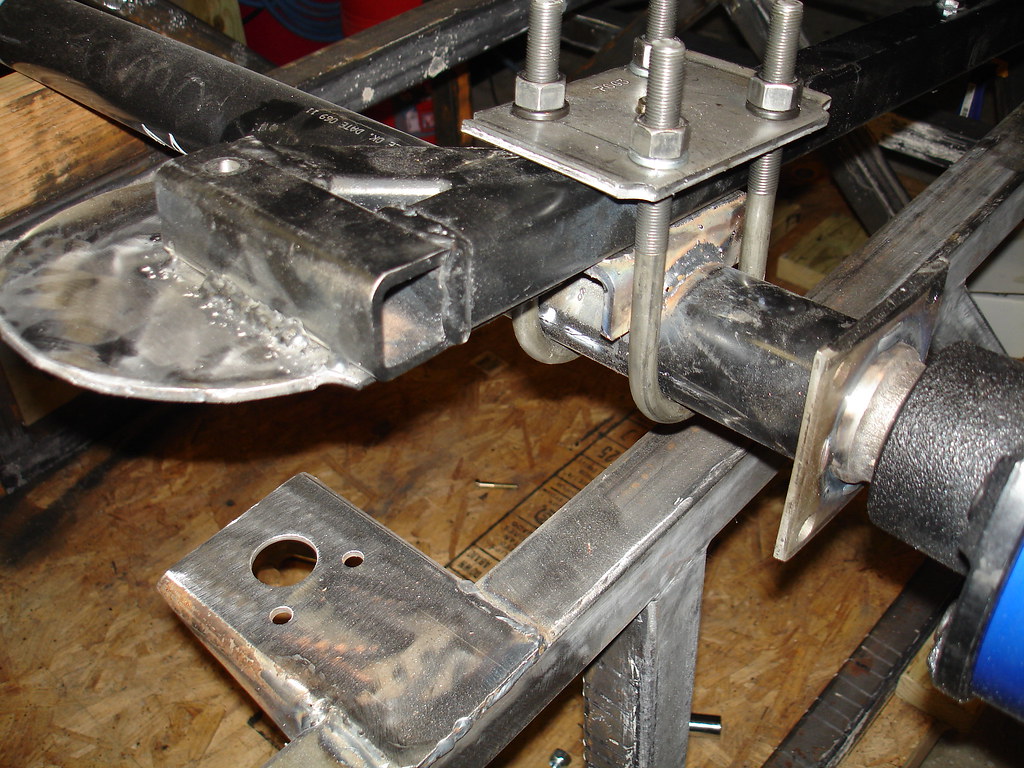

Next I cleaned up all the welded edges to prep for welding. I laid out the top frame first for welding.

After I tacked the top frame all up, I laid out the frame and started welding it together.

After fully welding the frame and the top rail, I ground down the welds on top of the frame and the bottom of the top rail. I laid them on top of each other here for a picture.

Then I cut, tacked, and welded in the corner uprights and then attached the top rail.

And that's where I got today. I rolled in a wheel and put it by it to give an overall glimpse of what it will one day by.

At first I wanted an M416. I found one in Houston and made the drive down and picked it up and drug it home. After tinkering with it for a few months, I realized it wasn't what I really wanted. There is so much prep work with an average condition M416 that I figured I could scratch build me something for the same costs and time.

If you are local to the DFW area, you might have seen my thread so far on the LSJC website.

This is 2 months work so far.

1st, I cleaned up the garage and bought some supplies. The garage was a mess with crap everywhere.

1st order of duty was to build a flat (most concrete floors are not flat) level surface.

That was all I got done last night.

This morning the real work started. I started by laying out my plan on the plywood platform. I used some 2x4 scraps to build a fixture to hole parts in place and assist with assembly.

On a side note, if you are goin to cut a lot of steel, buy one of these. Its a Milwaukee Dry Cut saw

It cuts in 1/10 the time a fiber wheel does, no sparks, its precise, almost zero burs, and no black dust. Then get a magnetic broom and you just pick up the clips in a nice quick swipe.

Back on subject, I started cutting the steel and making sure everything fit and was aligned. It was.

Here is the lower frame all laid out.

Then I cut the upper frame. Here it is just placed on the lower frame.

Next I cleaned up all the welded edges to prep for welding. I laid out the top frame first for welding.

After I tacked the top frame all up, I laid out the frame and started welding it together.

After fully welding the frame and the top rail, I ground down the welds on top of the frame and the bottom of the top rail. I laid them on top of each other here for a picture.

Then I cut, tacked, and welded in the corner uprights and then attached the top rail.

And that's where I got today. I rolled in a wheel and put it by it to give an overall glimpse of what it will one day by.