This is how I do all my lights. I have put lights on every vehicle I have owned, and many others.

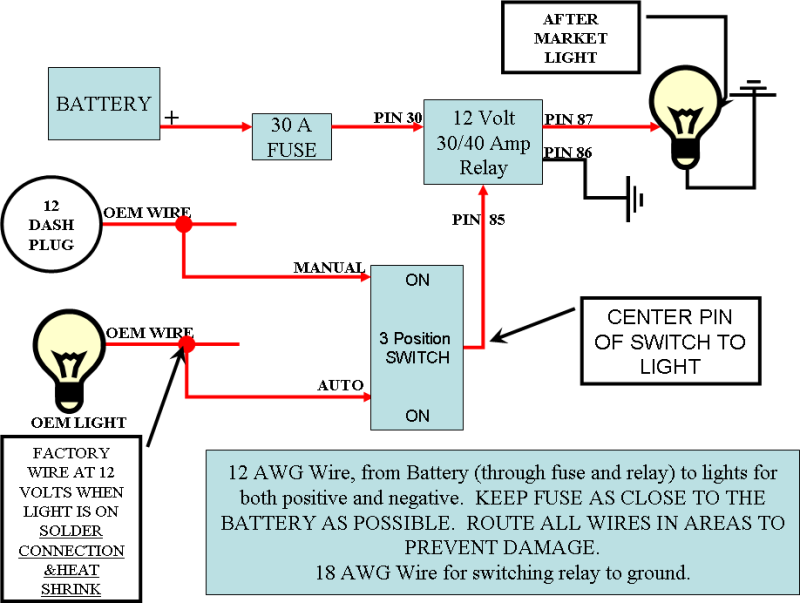

You will want to make sure they are fed from a keyed power supply or controlled by something like your headlights I normally do both so I can have a manual and auto setting.

For me I take wiring very seriously, as a few pennies pinched can cost you your vehicle very quickly and when I do something I never want to do it again so do it right the first time.

For things like lights I only use parallel bonded, jacketed wire or (duplex brake cable) for everything either 12/2 for the high current side of the relay from the battery to the lights and 18/2 for the switching side of the relay. It keeps everything very clean and easy to route and I HATE split loom.

All my connections into the factory harness are soldered and then heat shrinked, this just ensures that I never have to worry about corrosion on my wires later and that the factory harness is not weakened in any way. I never cut a factory wire to do this I just strip 1/2" of insulation and solder to the wire.

Everything on a vehicle at some point is going to have to come off or be moved so I always use weather-pack connectors at the ends of all connections to lights, fans, compressors, and behind the dash to make easy removal when the time comes without having to cut wires to do things. I also use weather-pack style HELLA relays and fuse holders. I had 10 years on my last truck and I never had to rewire anything or even blew a fuse.

Here is how I have my Fog lights, off road lights, backup lights, and train horns wired in.

The below diagram is for 1 PAIR of lights or up to a 30 load on the relay.