Here is a post I put together for another forum regarding data from my upgrade:

Due to me being solo for this and a lack of any scientific equipment other then a wheel with a built in counter (no idea what it's called), these numbers have a high chance of error...so please don't take these stopping distances as gold. What I think is important is the changes between and overall average of each setup.

Vacuum, 1/2t calipers, 1/2t pads, 265 tires, stock height

1st pass - 138ft

2nd pass - 136ft

3rd pass - 135ft

Vacuum, 3/4t calipers, 3/4t Hawk LTS pads, Slotted rotors, 265 tires, stock height

1st pass - 146ft

2nd pass - 148ft

3rd pass - 142ft

HYDROBOOST, 3/4t Master, 3/4t PS pump, 3/4t calipers, 3/4t Hawk LTS pads, 285/70R17, 4.5" lift

1st pass - 134ft

2nd pass - 130ft

3rd pass - 129ft

Surprisingly, each day I did the testing, it was about 50deg.

Additional info:

- My shocks were not setup correctly when I did the hydroboost passes, so with firmer valving, I have a feeling a few feet will be knocked off

- During the hydroboost test, my truck was a few hundred pounds heavier with the lift kit, bigger tires and tools in the back

Some observations:

- DO NOT BUY 3/4T CALIPERS UNLESS YOU HYDROBOOST - you're stopping distances will INCREASE. Also, the 3/4t master will not bolt up to you vacuum system

- Hydroboost was able to finally lock the tires and create a small patch of rubber...my vacuum was not able to do that

Some negatives:

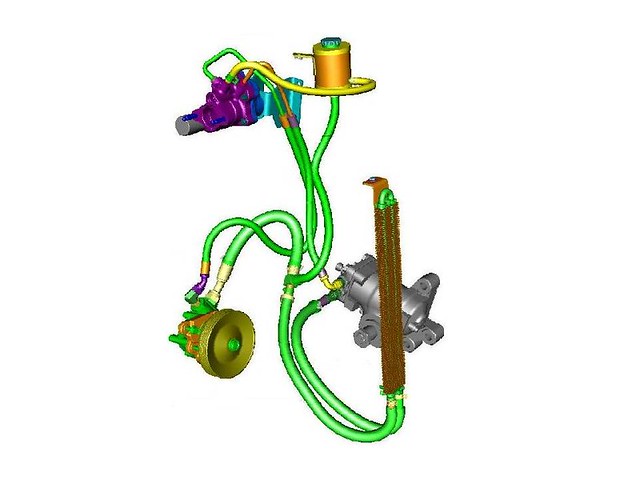

Using all new AC Delco parts (do not buy cardone), expect to spend $750+ and three days doing this for first timers. You're upgrading the master cyclinder, PS pump, hydroboost unit, GM variable assist bypass, three lines and possibly adding a Power steering cooler...this stuff adds up really fast. You can always go used and ppl have had a lot of success, but for brakes, I personally always buy new.

Hydro units have a propensity to leak and are expensive to have rebuilt. If you buy used, definitely get some kind of guarantee that if it leaks, you can return. My first (new AC Delco) unit leaked and it took a week to get another one...

Also, you will need to cut and re-flare brake lines...so definitely know what you're doing before you rip into your truck's braking system. This is a job that is straightforward, but definitely requires someone who is comfortable working on multiple components and understanding when something is installed correctly (i.e. always replace orings, use line wrenches and torque to the correct settings!)

Everyone has a different preference, but I really hate that i lost variable steering. My rig rode like a boat prior, once I bypassed my variable assist, steering got even softer. With the months of research I did, I could not find a hydroboosted truck that had variable assist....so plan on bypassing it b/c otherwise you will restrict the amount of fluid your hydro unit receives.

I hope this helps everyone in the endless quest to stop these rigs! Please feel free to ask any question you may have!!

Part #'s:

Power Steering Return Hose - AC Delco 36-368640

Power Steering Pressure Hose - AC Delco 36-365460

Power Steering Pressure Hose - AC Delco 36-365490

Power Steering Pump - AC Delco 36-517137

Master Cylinder - AC Delco 174-722

Hydroboost Unit - AC Delco 178-578

Variable Bypass - GM #19168825

OEM PS Cooler (from gmpartsgiant) - 26041420 & 15655032 (bracket)

A good writeup for the install -

http://www.gmfullsize.com/forum/showthread.php?t=156800