HuskerJeep

Adventurer

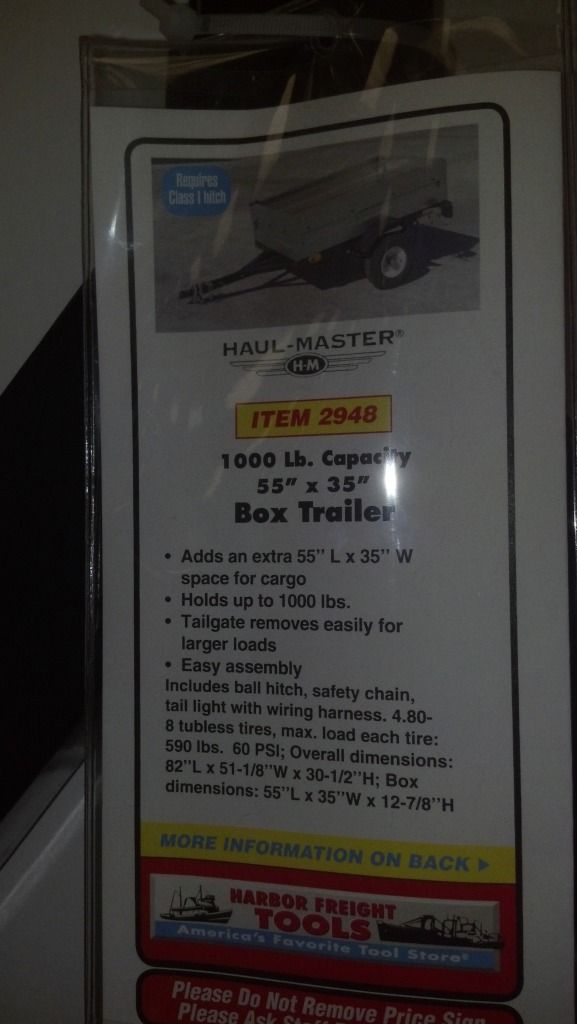

Hello everyone. I am Shawn from Nebraska and have been browsing this forum while getting some great ideas for my build. The desire to build a trailer all started from a friend of mine who purchased this trailer recently.

After seeing how fast he had it set up and the potential of what you could have readily available at any time camping, the urge to do something similar got the best of me and I haven't looked back since. :ylsmoke:

Since I have owned an older Appleby camper for a coupe years now, the thought of building something off of that crossed my mind, but that would have been too easy. After browsing the Harbor Freight website late at night, I did find a trailer that I thought would be great to use. It listed for $329 and was rated for 1000 lbs. The next day I drove to the store and saw it was on clearance for $229. That made the decision to by it pretty easy, BUT it was on backorder and they had no idea if they were even going to get any more in. Long story short, I bought the floor model minus the axle, wheels, tires, wiring, and tongue jack for $125. No biggie to me since I wasn't going to be using most of the stuff any way, and the stuff I would be using is cheap enough to buy separate.

After pricing stuff out at Tractor Supply and Orschlens I found out TS was pretty proud of what they had, so the drive all the way across town to Orchelns was pretty easy considering I would be saving myself $50-$60 on the exact same products.

More to come......

After seeing how fast he had it set up and the potential of what you could have readily available at any time camping, the urge to do something similar got the best of me and I haven't looked back since. :ylsmoke:

Since I have owned an older Appleby camper for a coupe years now, the thought of building something off of that crossed my mind, but that would have been too easy. After browsing the Harbor Freight website late at night, I did find a trailer that I thought would be great to use. It listed for $329 and was rated for 1000 lbs. The next day I drove to the store and saw it was on clearance for $229. That made the decision to by it pretty easy, BUT it was on backorder and they had no idea if they were even going to get any more in. Long story short, I bought the floor model minus the axle, wheels, tires, wiring, and tongue jack for $125. No biggie to me since I wasn't going to be using most of the stuff any way, and the stuff I would be using is cheap enough to buy separate.

After pricing stuff out at Tractor Supply and Orschlens I found out TS was pretty proud of what they had, so the drive all the way across town to Orchelns was pretty easy considering I would be saving myself $50-$60 on the exact same products.

More to come......