Master-Pull

Supporting Sponsor

I figured I would put up pictures of what we did last week, this was on a very clean Duramax. We get plenty of questions about installations and what is the proper way to get a rope onto your drum. I do some photo installs every so often and here is one we last week.

The guys from Bell Off Road came by with a truck they have been working on for Duck Dog Waterfowl that will be displayed at SEMA next year.

Here are the photos:

First step is a new fairlead. Start by getting the old steel rollers off, they can be reused if they are smooth and roll easily, other options include replacement rollers that are aluminum or a plastic. We use aluminum hawse fairleads with our rope, they are 100% made in the USA! This will help protect the rope as you use it, it will also lighten the front end and provide a better approach angle.

We decided on using 3/8ths inch Superline (rated to 24,000 lbs) for this 12,000 lb winch. It comes with our Aluminum Winch Stop Thimble, which is machined and anodized in the USA, and a Kevlar heat protector to help keep the rope from being damaged in the event the winch overheats.

We advise uncoiling the rope fully and laying it on a clean surface before you start, this will make it easier to install! If you don't have a very long shop to use you can always lay the rope out in an S shape.

Feed your rope through the fairlead and make sure it wraps underneath the winch. This will allow it to properly spool on and go through the fairlead at the correct angle.

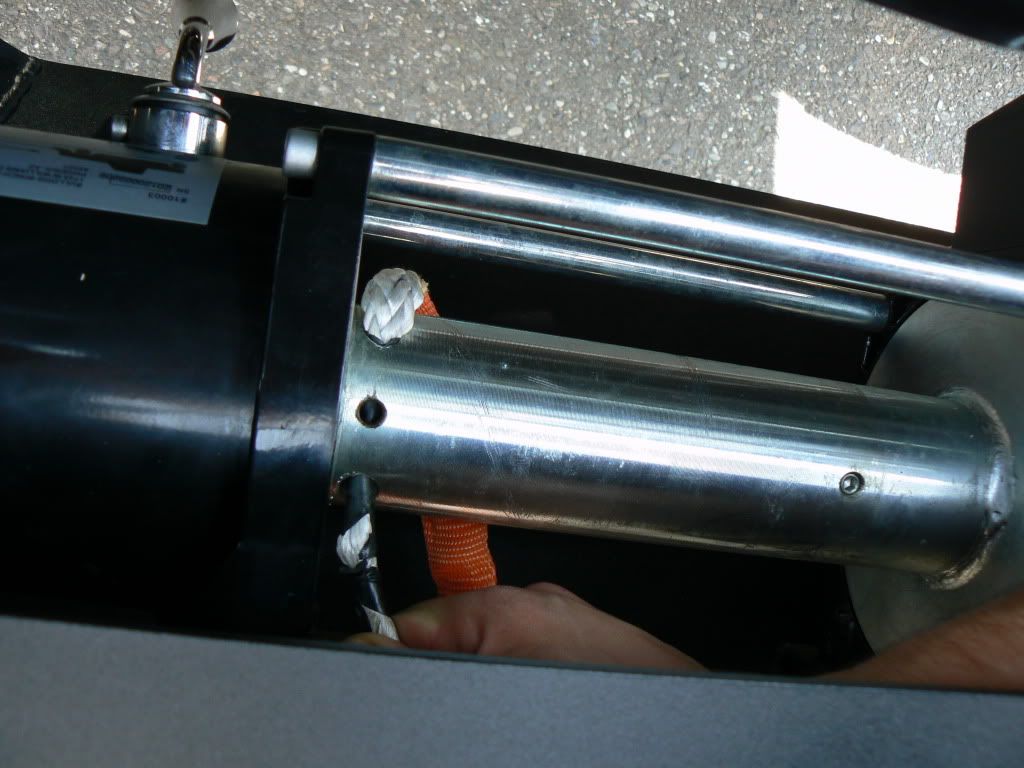

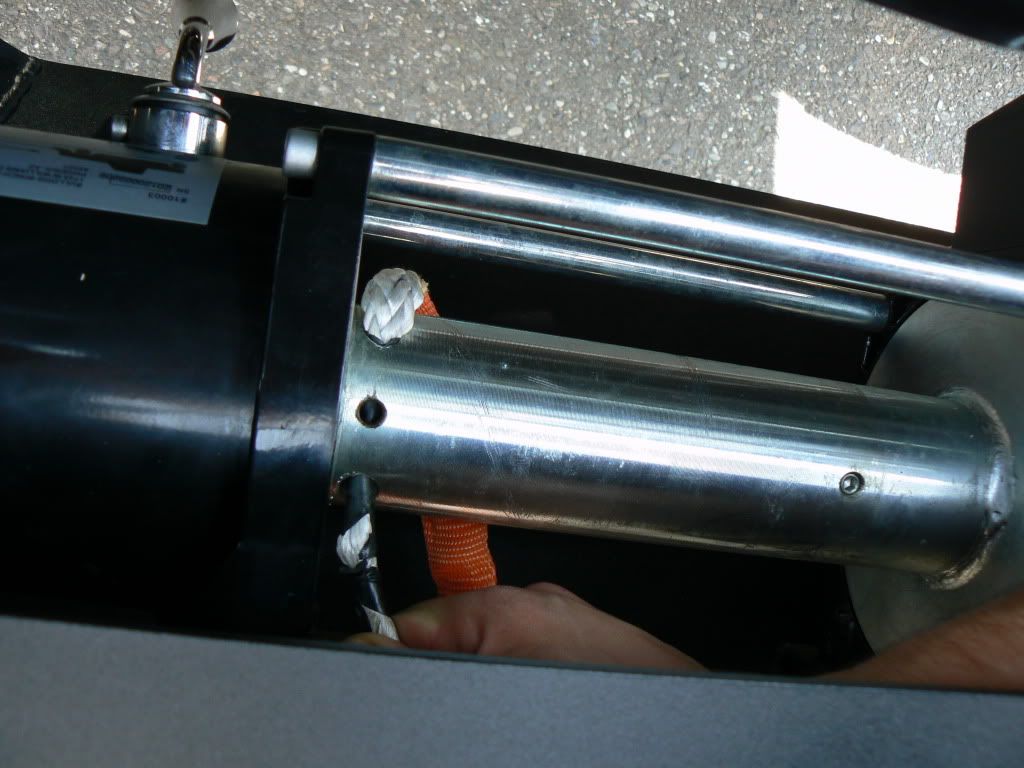

You can see where we had to put some tape around the end of the rope to pull it through the winch drum. If the rope is too large to fit through the whole in your drum then you can taper it by cutting a few strands 3-4 inches from the end. Then tape the rope back up so it is cone shaped. From here feeding it through should be a breeze.

Once the rope is snug inside the winch drum, cut off the excess so you have a smooth end. You can see the orange Kevlar heat protector that will cover the first layer of the drum to protect the rope from winch heat.

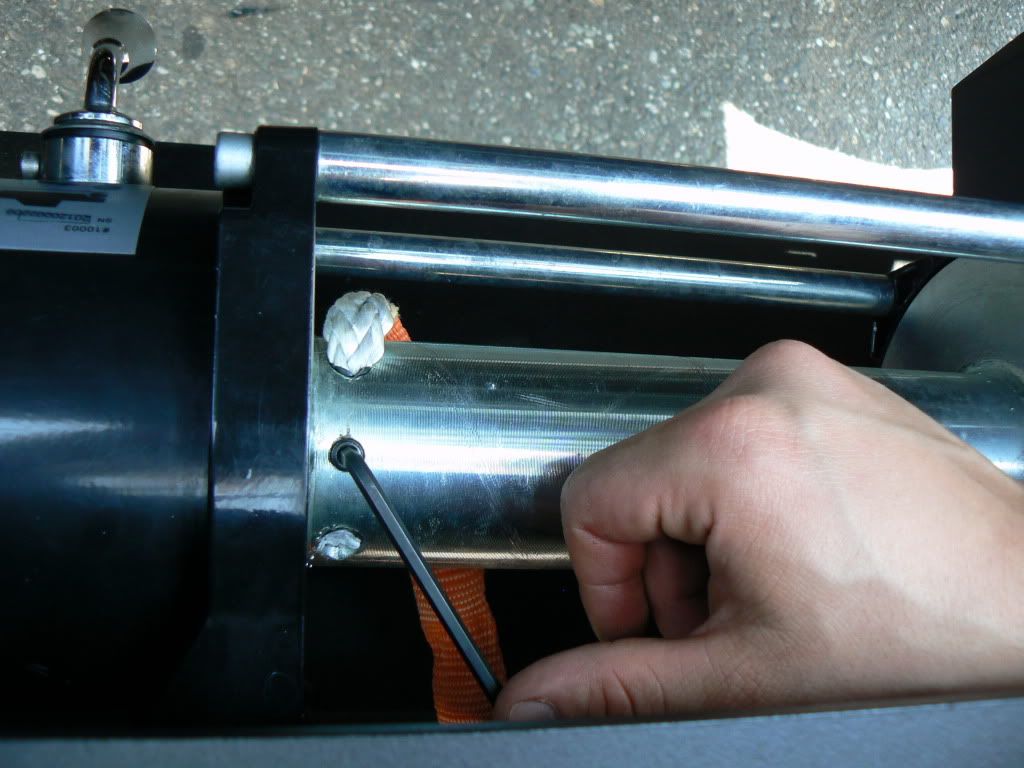

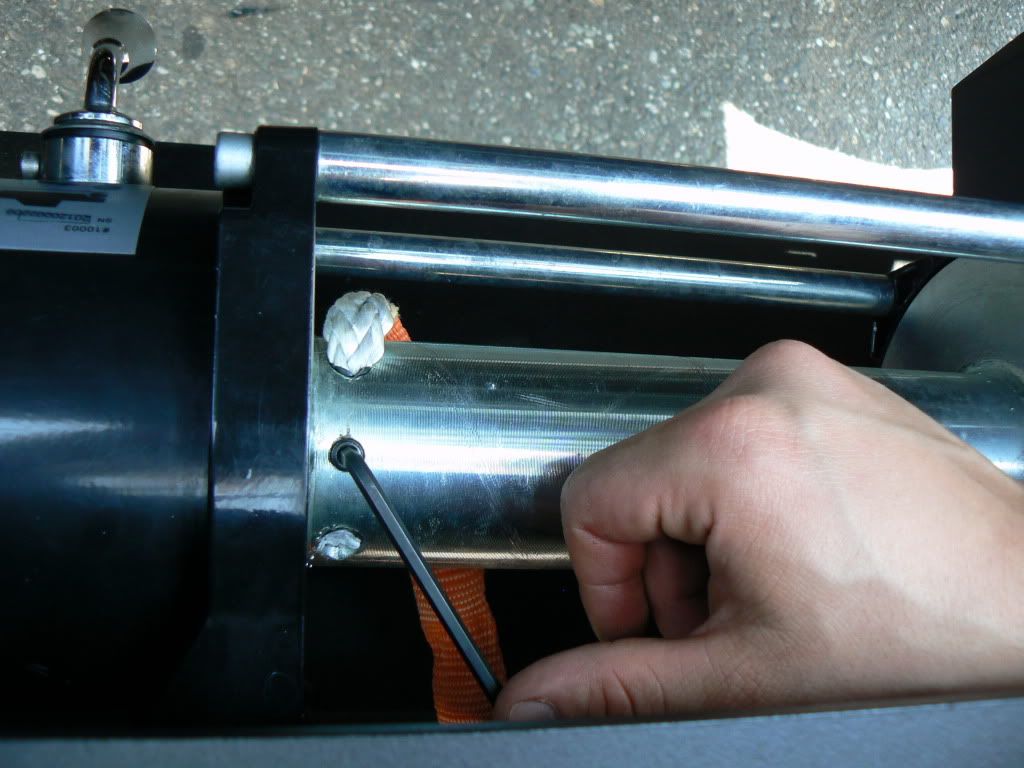

Use an allen wrench to tighten down the set screw and keep the rope firmly in place. Remember that this screw and in other cases our drum link are only there to hold the rope on when it being spooled on. You never want to have less then a 1 set of wraps around the drum when you are winching a vehicle, the wraps cinch tightly against the drum and hold the rope in place.

We advise always wearing gloves while winching. Keep your hands clear of the fairlead and slowly winch in keeping tension on the rope to help it spool in neatly and tightly.

Having someone working the winch controller while you spool in will free up both your hands to ensure a tight neat wrap.

The large base on the thimble makes sure it will never be pulled into the winch. Once it is snugged up you are all set to go.

-Alex

The guys from Bell Off Road came by with a truck they have been working on for Duck Dog Waterfowl that will be displayed at SEMA next year.

Here are the photos:

First step is a new fairlead. Start by getting the old steel rollers off, they can be reused if they are smooth and roll easily, other options include replacement rollers that are aluminum or a plastic. We use aluminum hawse fairleads with our rope, they are 100% made in the USA! This will help protect the rope as you use it, it will also lighten the front end and provide a better approach angle.

We decided on using 3/8ths inch Superline (rated to 24,000 lbs) for this 12,000 lb winch. It comes with our Aluminum Winch Stop Thimble, which is machined and anodized in the USA, and a Kevlar heat protector to help keep the rope from being damaged in the event the winch overheats.

We advise uncoiling the rope fully and laying it on a clean surface before you start, this will make it easier to install! If you don't have a very long shop to use you can always lay the rope out in an S shape.

Feed your rope through the fairlead and make sure it wraps underneath the winch. This will allow it to properly spool on and go through the fairlead at the correct angle.

You can see where we had to put some tape around the end of the rope to pull it through the winch drum. If the rope is too large to fit through the whole in your drum then you can taper it by cutting a few strands 3-4 inches from the end. Then tape the rope back up so it is cone shaped. From here feeding it through should be a breeze.

Once the rope is snug inside the winch drum, cut off the excess so you have a smooth end. You can see the orange Kevlar heat protector that will cover the first layer of the drum to protect the rope from winch heat.

Use an allen wrench to tighten down the set screw and keep the rope firmly in place. Remember that this screw and in other cases our drum link are only there to hold the rope on when it being spooled on. You never want to have less then a 1 set of wraps around the drum when you are winching a vehicle, the wraps cinch tightly against the drum and hold the rope in place.

We advise always wearing gloves while winching. Keep your hands clear of the fairlead and slowly winch in keeping tension on the rope to help it spool in neatly and tightly.

Having someone working the winch controller while you spool in will free up both your hands to ensure a tight neat wrap.

The large base on the thimble makes sure it will never be pulled into the winch. Once it is snugged up you are all set to go.

-Alex