Billoftt

Active member

All I know is I would LOVE to build one of those tops if I were to own a JKU.It uses the roof mold for my JKU Safari Cab to produce a longer roof for the Gladiator and would have canvas roll-up soft sides all around.

All I know is I would LOVE to build one of those tops if I were to own a JKU.It uses the roof mold for my JKU Safari Cab to produce a longer roof for the Gladiator and would have canvas roll-up soft sides all around.

I use 1/8" x 1" EPDM for all of the joints; for the joint between the top and back panels I put EPDM on both parts so there's a double seal. Haven't had any problems with sealing.Hey Jeff, I'm glad you got a 2-door to finally install onto! What are your methods of weatherstripping/sealing the interfaces? The interface between the rear and top panels is vertical, and is one of my problem areas for leaking in rain and snow, especially while moving. I've put EPDM foam tape to act as a weatherstrip gasket, but it doesn't lend itself to repeated reinstalls.

I use 1/8" x 1" EPDM for all of the joints; for the joint between the top and back panels I put EPDM on both parts so there's a double seal. Haven't had any problems with sealing.

What's important is that the flanges of both parts mate exactly - if they're exactly in the same plane there's not much for the weatherstrip to do but if they're not exact, say one is a few degrees off from the other then there's more reliance on the weatherstrip. This is why when I converted the top I showed joining the flanges to each part when the parts are assembled and the flanges are bolted together - that way when the epoxy cures the flanges mate exactly.

Why don't you post some photos of your conversion - I'm sure people would like to see it!Got it - I may have some body filler work to do!

Why don't you post some photos of your conversion - I'm sure people would like to see it!

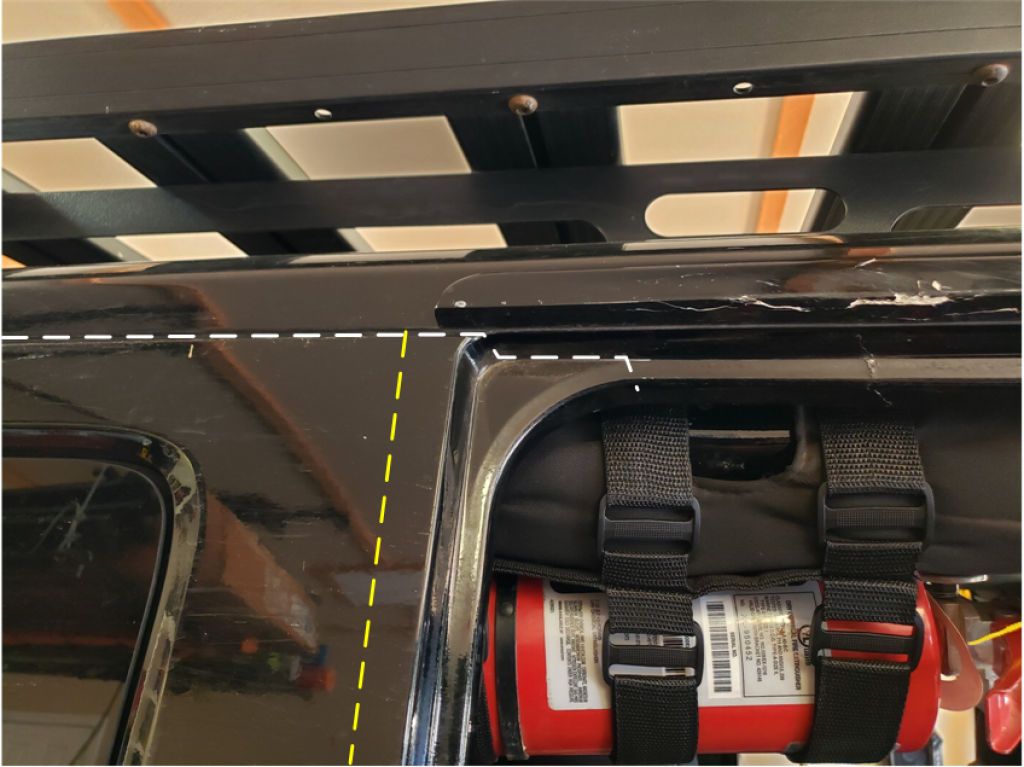

If I were doing it I would probably cut it as shown below. The white line separates the roof from the side panel and the yellow line separates the c-pillar from the side panel for use with roll-up soft sides. If you don't plan to ever do roll-up soft sides you don't need to have a separate c-pilalr so you can eliminate the yellow cut. I would build up the inside of the cut line in the door jamb so weatherstrip could go between the two pieces.Hey Jeff, how would you go about the cut at the front edge of the 4dr roof? I skimmed back thru and searched, but didn't see anything. Thanks.

Converting a JL hardtop to modular should work out just fine using the steps and materials as described in this thread.I would love to do a modular roof for my JL with the OEM soft top windows and a hard roof. Braced from the inside (ala Maximus-3 rack) so imagine this but with no windows

This is how I usually run it so a hard shell would be nice for roof storage:

View attachment 553429