volcomsurfer

Adventurer

So what are the advantages and disadvantages of securing a floor to the van? I'm not sure how much the body flexes and if it needs some give. I was planning on securing the cabinets to the wood floor and to the walls of the van, so it will still be pretty secure in its own right.

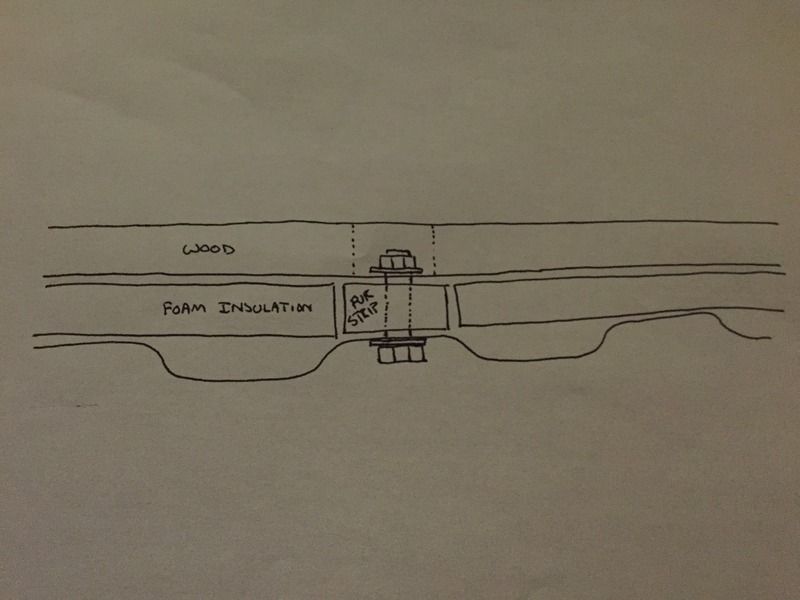

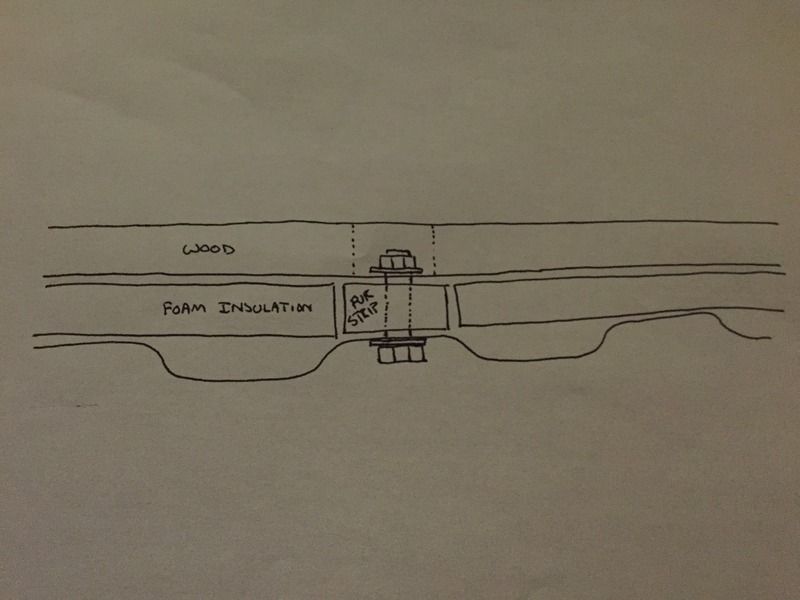

So foam board, then wood on top is the plan. I'm thinking about running furring strips and putting a bolt through the floor of the van and the furring strip. Then just use wood screws to secure the wood floor to the furring strips. It would be a pain in the *** to take it apart if I have to, but it will be solid.

Is this overkill or a good idea? Also, any opinions on using OSB for the subfloor?

Here's the idea..

So foam board, then wood on top is the plan. I'm thinking about running furring strips and putting a bolt through the floor of the van and the furring strip. Then just use wood screws to secure the wood floor to the furring strips. It would be a pain in the *** to take it apart if I have to, but it will be solid.

Is this overkill or a good idea? Also, any opinions on using OSB for the subfloor?

Here's the idea..