jscherb

Expedition Leader

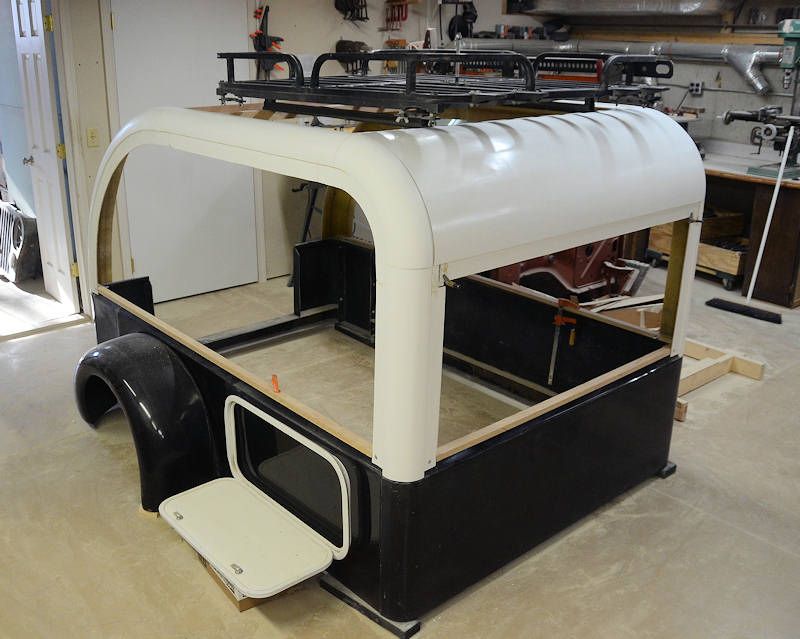

I decided to put the second layer of 1/8" plywood skin on the hatch "the hard way"... by that I mean I oriented it 90 degrees differently from the first layer. The first layer was put on with the grain of 2 of the 3 plies running crosswise - that way it bent very easily around the curve. I decided to run this one the other way so that the final laminate of two layers of plywood had the same number of plies running in each direction for maximum strength. I'm sure putting both layers the "easy way" would have been plenty strong enough, but I wanted to see how hard it would be to do it the other way.

Answer: it takes a lot more clamps. I used ratchet straps to pull the plywood into shape, the straps are attached to pipes running through cinder blocks on the floor. Then I use clamps around the perimeter.

I used Titebond III wood glue - it's waterproof and it's also thin enough to be spread easily with a paintbrush, so I could coat the entire surface of the plywood quickly with glue.

I'll let it set up overnight and tomorrow it'll get installed on the camper shell.

Answer: it takes a lot more clamps. I used ratchet straps to pull the plywood into shape, the straps are attached to pipes running through cinder blocks on the floor. Then I use clamps around the perimeter.

I used Titebond III wood glue - it's waterproof and it's also thin enough to be spread easily with a paintbrush, so I could coat the entire surface of the plywood quickly with glue.

I'll let it set up overnight and tomorrow it'll get installed on the camper shell.